Description

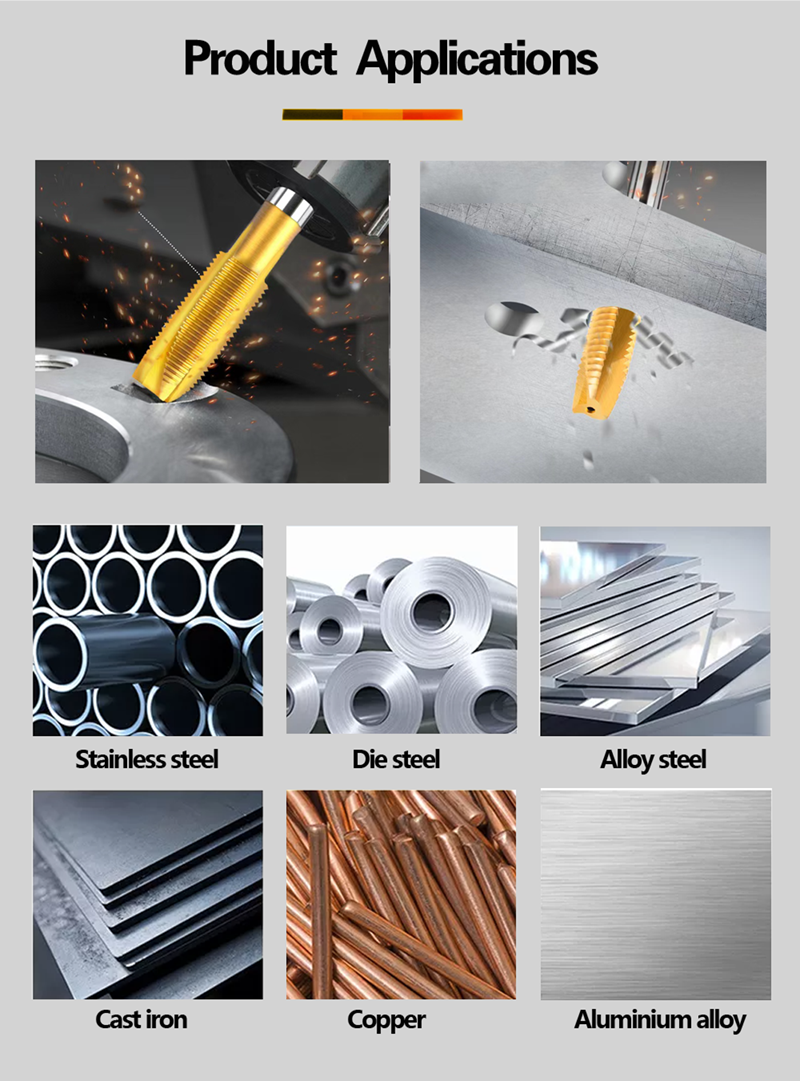

Spiral Point Tap Bit HSS Cobalt Tungsten PVD coating

One-Stop Shop for Cutting-Edge Manufacturing Solutions

Spiral point tap bit generally have 4-5 cutting edges, which further reduces the amount of cutting per tooth, thereby increasing the service life of the tap. In addition, its cutting speed can generally be increased by more than 50% compared with spiral flute taps, which greatly improves processing efficiency. Due to these advantages, spiral tip taps should be used first when tapping through holes unless there are special requirements.

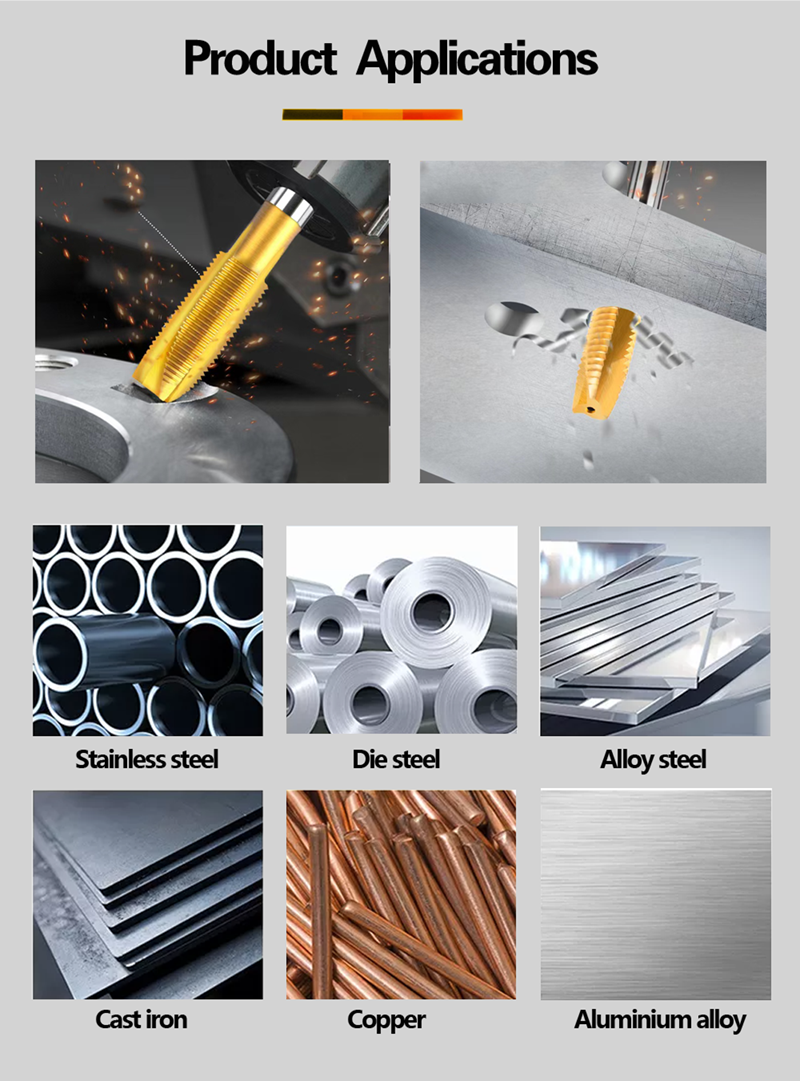

Spiral tip taps are mainly used to process parts with large specifications and long threads in thin-walled tubes, such as engine cylinder head threads and valve plate threads for automobiles, motorcycles and other equipment. When using a spiral tip tap, it is necessary to ensure that the entire cutting part is penetrated, otherwise tooth chipping will occur. At the same time, appropriate taps must be selected according to the hardness of the material being processed.

Spiral Point Tap Bit HSS Cobalt Tungsten PVD coating

Product Enquiry

Reviews

There are no reviews yet.