Description

Normal Tap Bit For Tapping Machine With High Precision

One-Stop Shop for Cutting-Edge Manufacturing Solutions

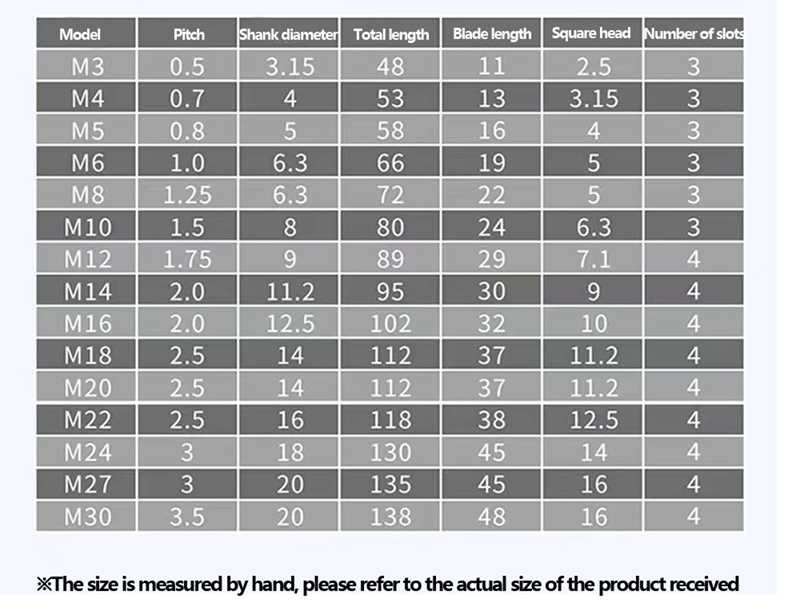

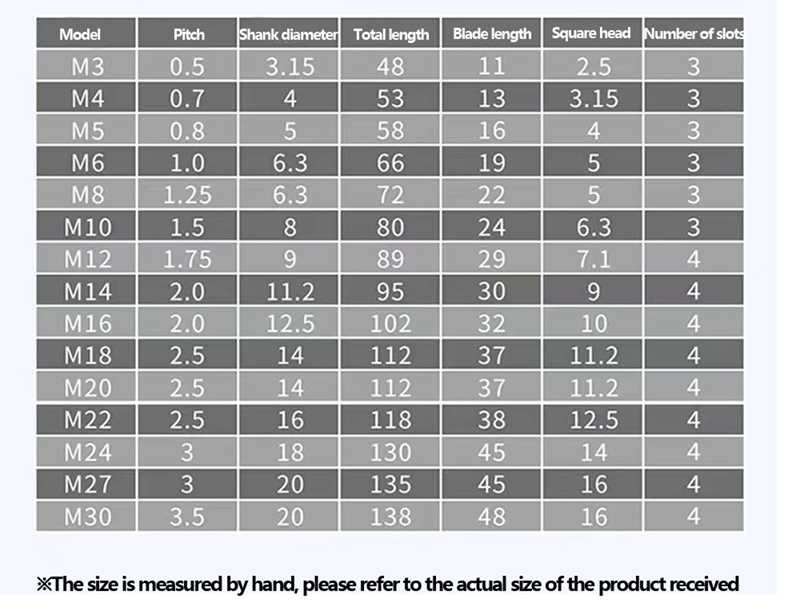

The manufacturing process of normal tap bit includes steps such as material selection, heat treatment, precision machining, surface treatment and quality inspection. Common materials include high-speed steel and carbon steel. High-speed steel has high hardness, high wear resistance and high temperature stability, and is suitable for manufacturing high-quality taps. Precision machining is the precise shape and size processing of taps through CNC machine tools and other equipment to ensure the geometric shape and dimensional accuracy of the taps. Common heat treatment methods include quenching, tempering and surface carburizing. Surface treatment is to improve the surface quality and corrosion resistance of the tap. Common surface treatment methods include chrome plating, galvanizing, spraying, etc.

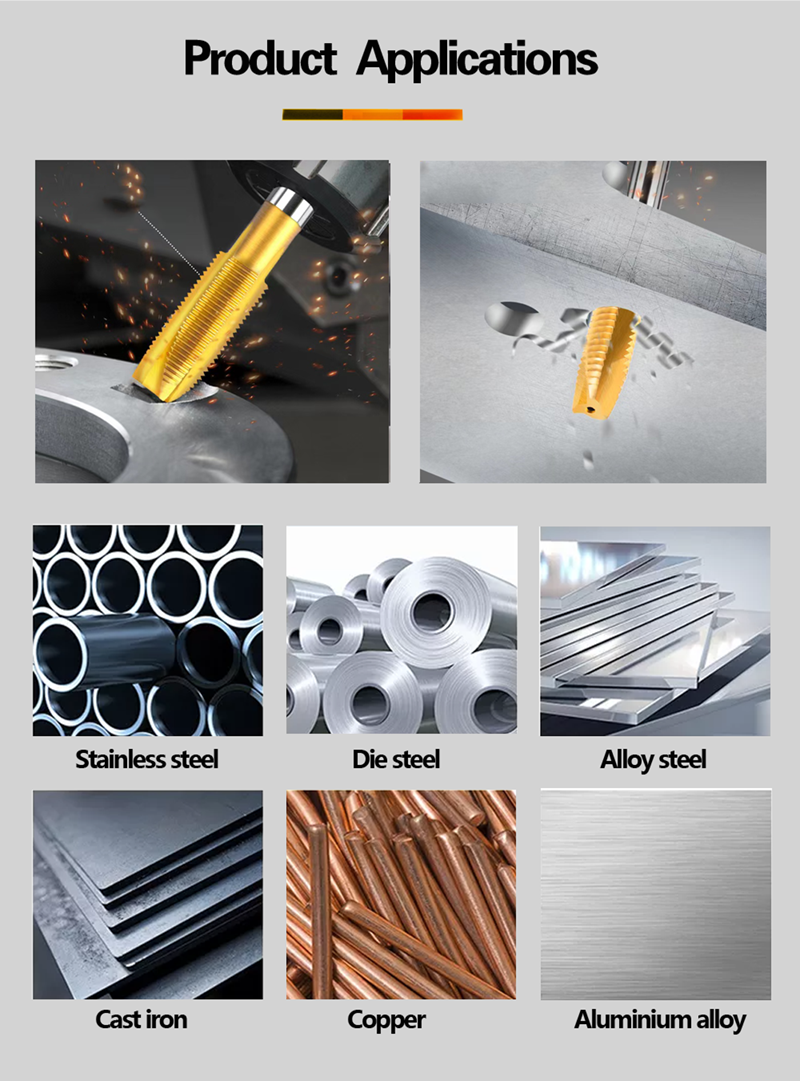

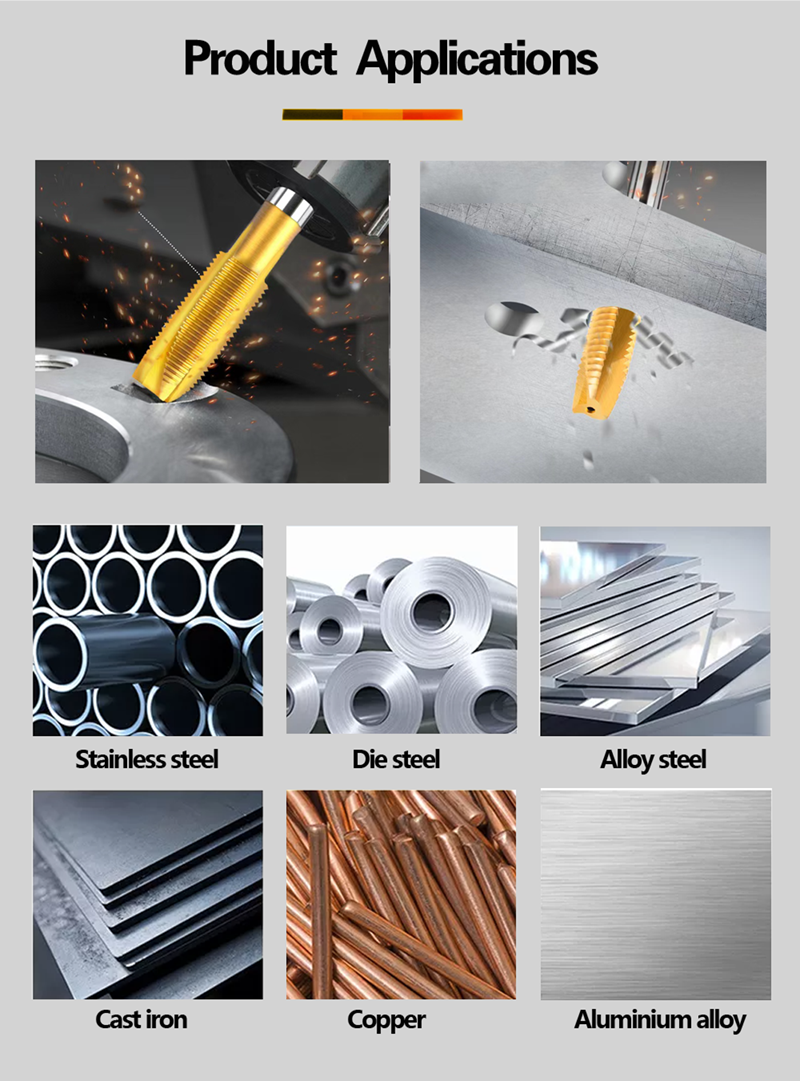

Taps are widely used in machinery manufacturing, automobile repair and construction. In mechanical manufacturing, taps are used to process various threads to manufacture pins, nuts, bolts, etc.; in automobile repair, taps can be used to repair damaged threads on wheel bolts and other related parts; in the construction field, taps can be used to Cut the water and air pipes so that the rebar can be placed and secured.

Normal Tap Bit For Tapping Machine With High Precision

Product Enquiry

Reviews

There are no reviews yet.