Drilling Machine And Tapping Machine -The advantages and disadvantages

1.Advantages of tapping machine:

Efficient and fast: Tapping machines are usually driven by compressed air, which can achieve fast and efficient tapping operations.

High torque: Under low air pressure and air volume, the tapping machine can output extremely large torque and is suitable for tapping various materials.

Wide scope of application: The tapping machine can tap various steel, iron, copper, aluminum, plastic and other materials without breaking the wire easily.

High precision: The tapping machine is equipped with an overload protection device, resulting in less damage to the tapping and high thread precision.

The operation is simple: hold the motor, align the hole, and press the start button to start tapping. After tapping to the predetermined depth, press the exit button and the tap head will automatically exit, completing a tapping operation.

Low processing cost: Compared with CNC machining centers, milling machines with tappers or manual tapping, the processing cost of tapping machines is lower.

2.Disadvantages of tapping machine:

Handheld tapping machines have low tapping efficiency: Compared with desktop tapping machines, handheld tapping machines require more time and patience to complete the same amount of work.

Short service life: Handheld tapping machines are usually powered by batteries, so their service life is relatively short and the batteries need to be replaced frequently, which increases the cost of use.

Easily damaged: Because handheld tapping machines are used frequently and often in harsh working environments, they are more susceptible to damage. Its parts are generally small and easily damaged, such as cutting heads, motors, etc.

Not suitable for large-scale use: Due to the disadvantages of low tapping efficiency, short service life and easy damage of hand-held tapping machines, it is not suitable for large-scale use.

3.Advantages of drilling machine:

Efficient and fast: The drilling machine adopts advanced drilling technology and equipment, which can complete a large number of drilling operations in a short period of time and improve work efficiency.

High drilling accuracy: The drilling machine can accurately drill long and deep holes, ensuring the dimensional accuracy of the processed parts.

Wide range of applications: Drilling machines have a wide range of applications and can be used in fields such as construction engineering, bridge construction, tunnel construction, and mining engineering.

4.Disadvantages of drilling machine:

Less power: Compared with some large drilling equipment, the power of the drilling machine may be smaller, and the drilling depth and drilling diameter are limited.

Requires hand-held operation: Drilling machines often require hand-held operation, which may cause fatigue when used for long periods of time.

Accuracy Limited by Operator Skill: Although the drilling machine itself is highly accurate, the operator’s skill level also affects the final drilling accuracy.

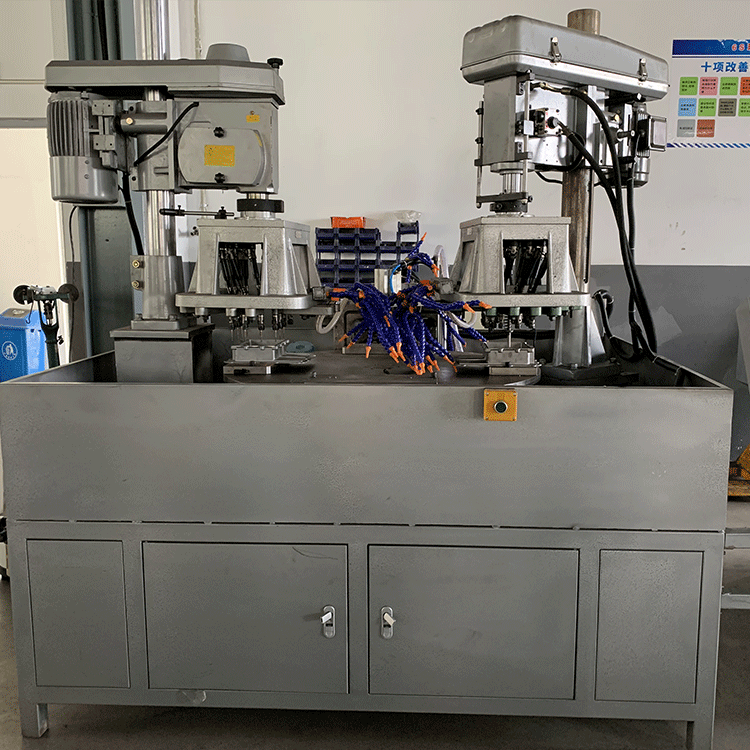

Although drilling machines and tapping machines each have their own advantages and disadvantages, they can also work together at the same time to bring convenience to humans.