Description

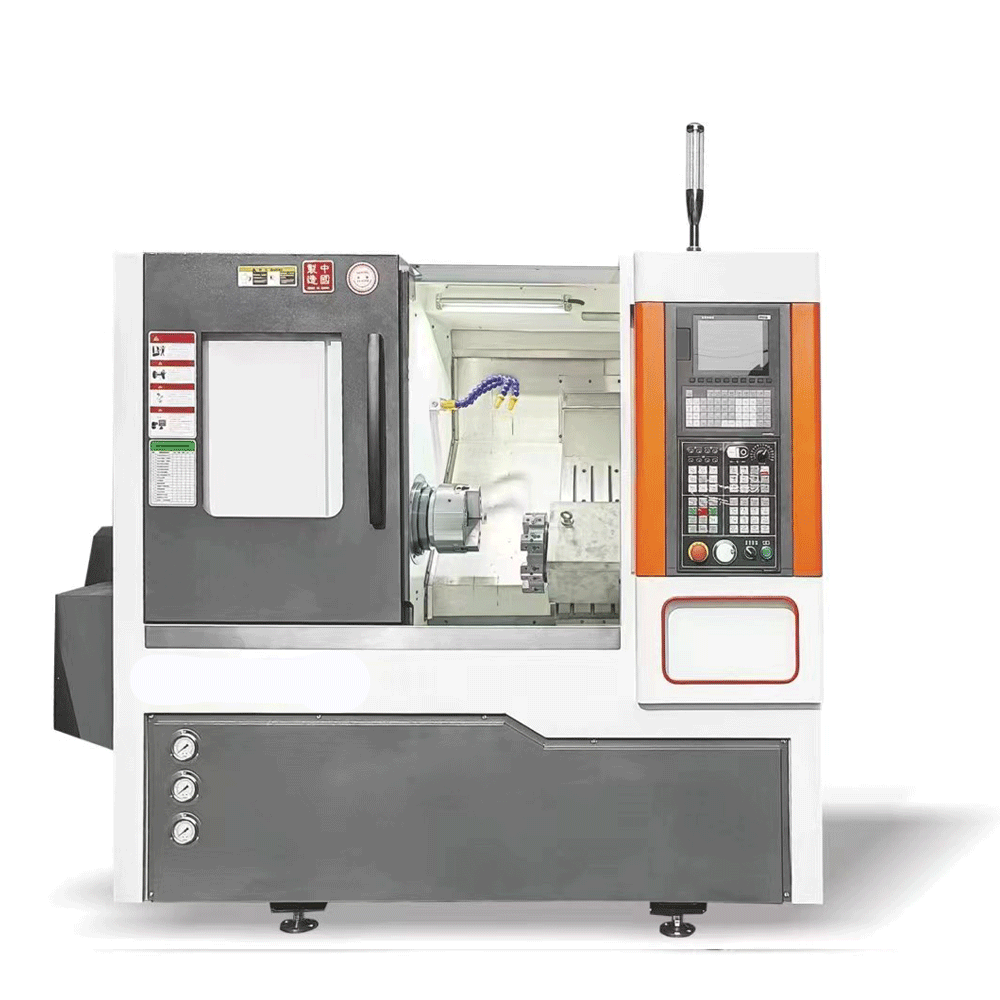

CNC Lathe Machine Automatic With High Quality And Precision

1.High precision: The CNC lathe machine adopts a high-precision CNC system, which can accurately control the movement of the machine tool to ensure the processing accuracy. This enables it to produce high-precision parts and meet the high requirements of modern manufacturing industry for product quality.

2.High efficiency: The CNC lathe can automatically complete complex processing tasks, greatly reducing manual intervention and improving production efficiency. In addition, due to its high precision and high efficiency, it can reduce the scrap rate in the production process and further improve production efficiency.

3.Flexibility: The CNC lathe has strong flexibility and can adjust the machine parameters and programs according to different processing requirements to achieve a variety of processing tasks. This enables it to adapt to various production needs and meet the personalized needs of customers.

4.Easy maintenance: The CNC lathe has a complete fault detection and alarm system, which can detect and eliminate faults in time. At the same time, its maintenance and maintenance are relatively simple, reducing maintenance costs.

5.High degree of automation: The CNC lathe has a high degree of automation in the processing process. Except for blank processing and clamping, most processing tasks can be completed automatically by the machine tool, reducing the labor intensity of workers and improving work efficiency.

6.Strong adaptability: When the processing object changes, the CNC lathe only needs to change the program to meet the new processing requirements, without the need to redesign the tooling, which greatly saves production preparation time.

7.Convenient production management: CNC machine tool processing parts can accurately calculate the processing time of parts, and simplify the inspection and management of fixtures and semi-finished products, which is conducive to the modernization of production management.

Max. Length of Workpiece (mm): 400

Machining Capacity :Light Duty

Spindle Bore(mm) :40

Spindle Motor Power(kW) :5.5

No. of Spindles: 12

Number of Axes: 3

Travel (X Axis)(mm): 800 mm

Travel (Z Axis)(mm): 420 mm

Place of Origin: Zhejiang, China

Tool Post Stations 4

Weight (KG) :2300

Warranty :1 Year

Applicable Industries :Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Key Selling Points: High-accuracy

Showroom Location :None

Marketing Type: Ordinary Product

Machinery Test Report :Provided

Video outgoing-inspection: Provided

Warranty of core components :1 Year

Core Components :Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Other, Gearbox

Max. Spindle Speed (r.p.m) :6000 r.p.m

Max. Weight of Workpiece(kg): 100

Width of bed (mm) :120 mm

Max. Turned Length (mm): 290

Positioning Accuracy (mm): ±0.003

Repeatability (X/Y/Z) (mm) :±0.003

Dimension(L*W*H) :1920*1550*1650mm

Model Number :400

Voltage :380V

CNC or Not :CNC

Machine Type :Lathe Machine CNC

Name High Precision :CNC Lathe Machine

Max. Swing Diameter :400mm

Maximum workpiece length: 400mm

Precision :0.003mm

Power(W) :5.5KW

Chuck Manual: 3 Jaw Chuck

Spindle speed :100-6000

Color :Customers’ Requirement

Packaging and delivery

Packaging Details :Each multi spindle head is wrapped with stretch film or packed in a wooden case.

Port :ningbo/shanghai

Reviews

There are no reviews yet.