Description

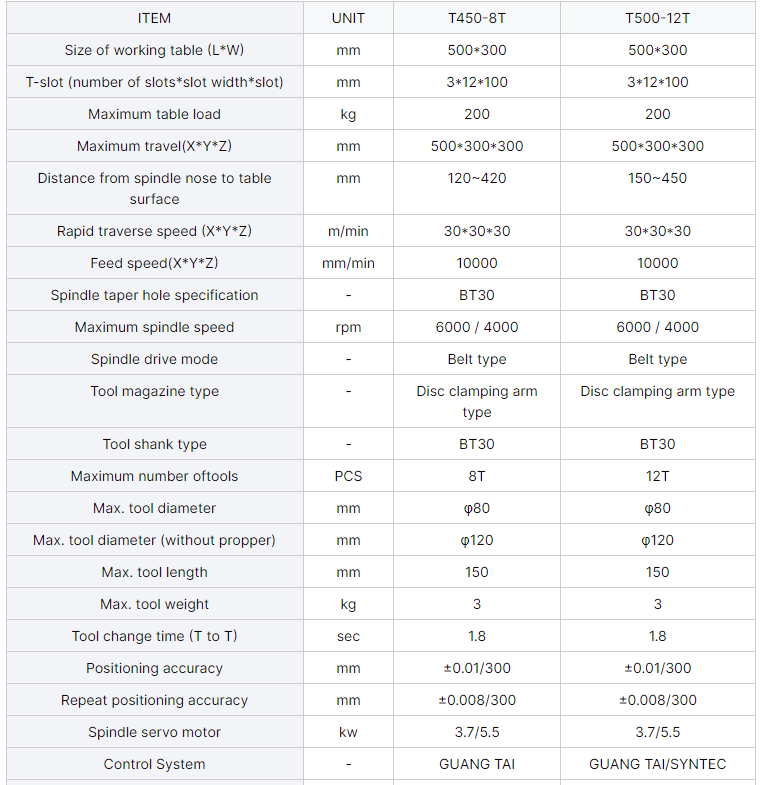

Powerful Drilling Center Series Lathe Machine T450-8T

One-stop service for R&D, design, production and manufacturing of various kinds of automatic drilling/tapping machines, automatic assembly machines CNC lathes and Drilling Tapping Center.

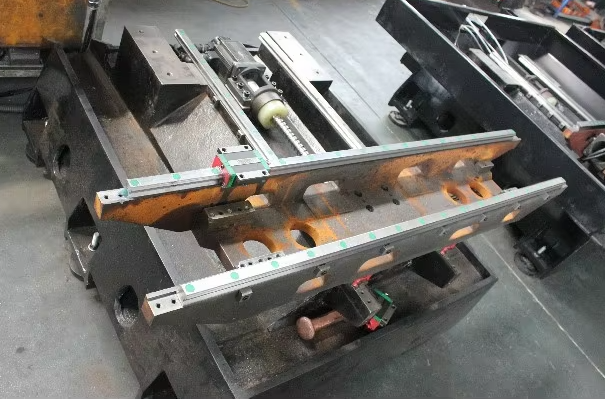

MACHINE FEATURES: 1.Machine tool gross also adopts resin sand precision casting, large span herringbone column, stable support,and after the second artificial aging treatment, to ensure the machine 2.The machine is compact in appearance, occupies little space, and can enter most of the freight elevators,saving the user’s resources on the ground floor of the plant. 3.The machine is equipped with standard locking tool holder, shank holder and tool box, which is very convenient for users to use. PRODUCT INTRODUCTION: 1.Adopting clamping arm type tool magazine, sequentialtool selection, stableand reliable tool change 2.Adopting high rigidity spindle motor, mainly used for drilling and tapping of steel parts, cast iron parts and copper and aluminum parts, as well as light-load milling processing, with great versatility and excellent performance. Advantages of roller guideway: High precision: Roller guide can realize micron-level positioning accuracy to meet the needs of high-precision equipment. Rigidity: able to withstand large loads, under the load of small deformation to ensure the stability of the equipment and precision of high-speed. Roller guide supports higher running speed, to adapt to the needs of high-speed equipment. Long life: has a long service life, can realize millions of times the number of cycles, to ensure the long-term stable operation of the equipment.

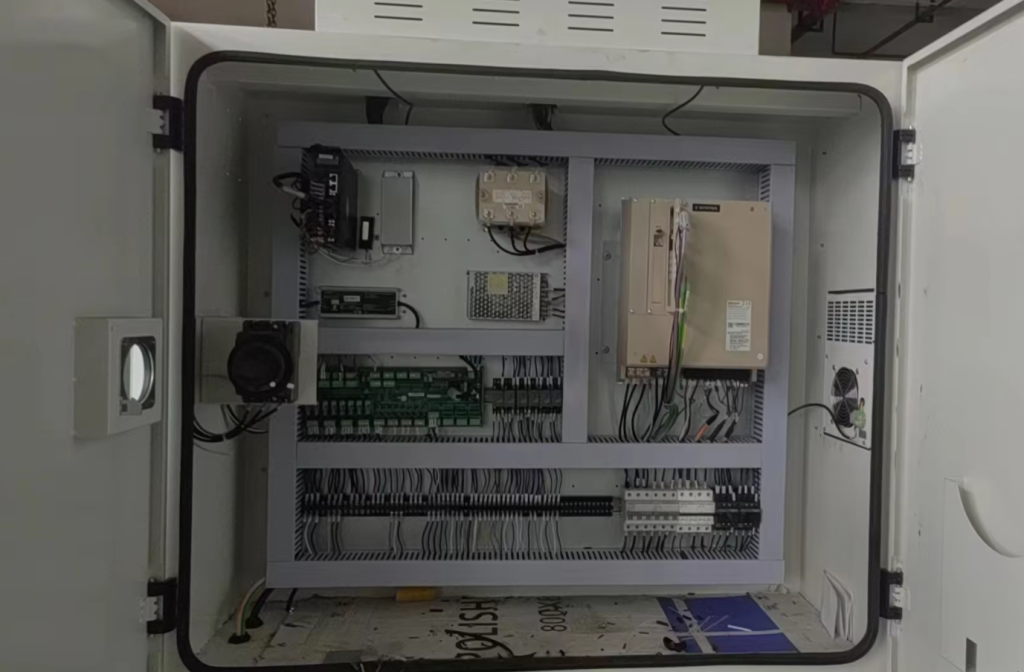

Main Components:

Bed: The foundation that supports the machine and absorbs vibrations.

Headstock: Contains the motor and spindle, which holds and rotates the workpiece.

Tailstock: Supports the other end of the workpiece and can hold tools for drilling.

Carriage: Holds the cutting tool and moves it along the workpiece.

Cross Slide: Allows for lateral movement of the cutting tool.

Cutting Tools:

Various cutting tools can be mounted for turning, facing, drilling, and threading operations.

Speed Control:

Adjustable spindle speeds to accommodate different materials and cutting operations.

Feed Mechanism:

Allows for manual or automatic feeding of the cutting tool along the workpiece.

Types of Lathe Machines

Engine Lathe:

A versatile and common type used in workshops for various turning operations.

CNC Lathe:

Computer Numerical Control lathes for automated and precise manufacturing.

Turret Lathe:

Features a rotating turret that holds multiple tools, allowing for quick changes during production.

Bench Lathe:

A smaller, more portable lathe ideal for hobbyists and small workshops.

Specialty Lathes:

Includes types like wood lathes, automatic lathes, and multi-spindle lathes, designed for specific applications.

Applications

Manufacturing: Producing cylindrical parts such as shafts, pins, and bushings.

Repair: Used in maintenance for repairing worn-out parts.

Prototyping: Essential for creating prototypes and custom components.

Woodworking: Shaping wood for furniture and decorative items.

Benefits

Precision: High accuracy in producing complex shapes and dimensions.

Versatility: Capable of performing a wide range of operations with different tools.

Efficiency: Reduces material waste and enhances productivity through automation (in CNC lathes).

Durability: Built to withstand rigorous use in industrial environments.

Reviews

There are no reviews yet.