Description

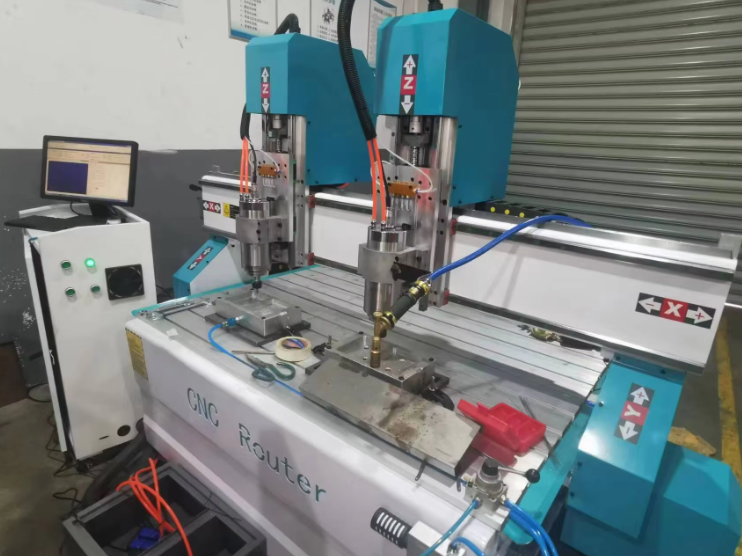

Laser Wood CNC Router

Key Features

- Computer Numerical Control (CNC): Operated via computer software, allowing for precise control over movement and cutting paths.

- Versatile Tooling: Capable of using different cutters, such as end mills, drill bits, and specialty bits, for various materials and applications.

- 3D Capability: Many CNC routers can create complex 3D shapes and designs, making them suitable for intricate projects.

- Large Work Area: Available in various sizes, accommodating large sheets of material, which is particularly useful for furniture making and large signage.

- Advanced Software: Typically comes with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software for designing and programming cutting paths.

Benefits

- Precision and Accuracy: CNC routers provide high levels of precision, ensuring consistent quality across multiple parts.

- Increased Productivity: Automating the routing process speeds up production times and allows for continuous operation.

- Flexibility: Can be programmed for various tasks, from simple cuts to complex engravings, adapting to different project requirements.

- Reduced Waste: Optimized cutting paths minimize material waste, making the process more efficient and cost-effective.

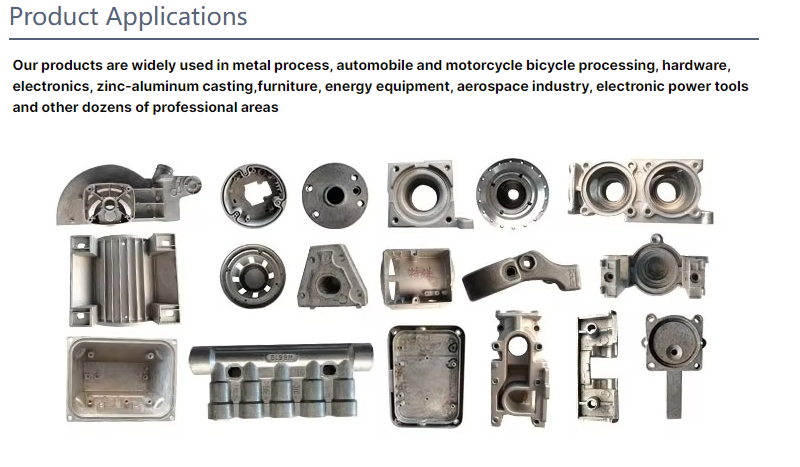

Applications

- Woodworking: Commonly used for cabinetry, furniture, and decorative items, allowing for intricate designs and patterns.

- Sign Making: Ideal for creating custom signs, letters, and logos with precision.

- Model Making: Used in prototyping and model creation in various industries, including architecture and engineering.

- Metalworking: Some CNC routers are capable of working with softer metals, expanding their versatility.

- Composite Materials: Suitable for cutting and shaping composite materials used in aerospace and automotive applications.

Reviews

There are no reviews yet.