Description

Pouch Food Grain Granule Spice Package Machine

Key Features

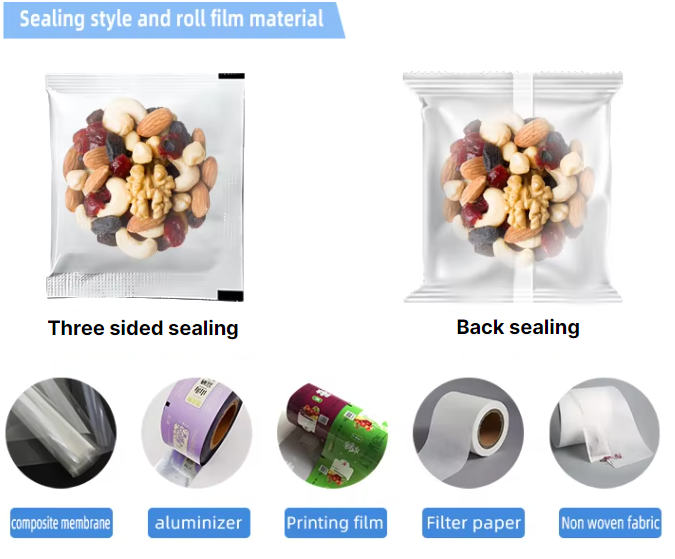

- Automation: Many packaging machines are fully automated, allowing for high-speed production with minimal manual intervention.

- Versatility: Capable of packaging different types of products, including solids, liquids, powders, and granules, in various formats (e.g., bags, boxes, bottles).

- Adjustable Settings: Users can modify settings for different product sizes, weights, and packaging styles, enhancing flexibility.

- Integration with Production Lines: Often designed to work seamlessly with other machinery in the production line, such as filling machines and sealing machines.

- Quality Control Systems: Equipped with sensors and monitoring systems to ensure consistent packaging quality and reduce errors.

Benefits

- Increased Efficiency: Automating the packaging process significantly reduces labor costs and speeds up production times.

- Improved Consistency: Ensures uniformity in packaging, which is critical for brand presentation and product safety.

- Enhanced Safety: Reduces the risk of workplace injuries by minimizing manual handling and repetitive tasks.

- Cost-Effectiveness: While the initial investment may be high, the long-term savings in labor and increased output often justify the cost.

Applications

- Food Industry: Used for packaging snacks, beverages, frozen foods, and ready-to-eat meals, ensuring freshness and safety.

- Pharmaceuticals: Essential for packaging medicines and supplements, where precision and compliance with health regulations are critical.

- Consumer Goods: Commonly used for packaging household products, cosmetics, and personal care items.

- Industrial Products: Employed in the packaging of tools, machinery parts, and other industrial goods.

Reviews

There are no reviews yet.