Precision Engineering with CNC Lathe: Enhancing Productivity and Quality

Modern manufacturing relies heavily on advanced technologies to achieve precision and efficiency. Among these technologies, CNC lathe(Computer Numerical Control) machines stand out, particularly CNC lathes, which are essential for turning operations and complex part fabrication.

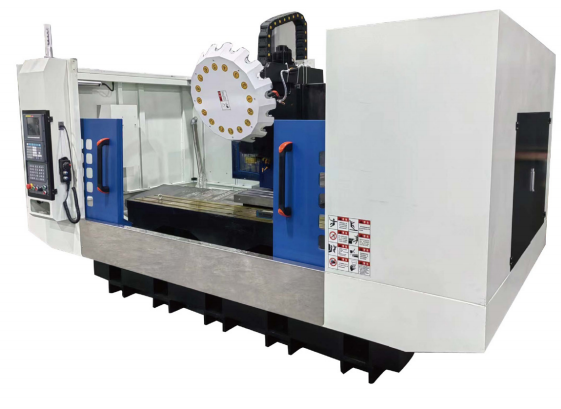

Understanding CNC Lathe Technology

At their core, CNC lathes are computer-controlled machines designed to perform turning operations automatically. These machines interpret digital instructions provided by CAD/CAM software, translating them into precise movements that shape raw materials into finished products. This process ensures a level of accuracy and repeatability that is difficult to achieve with manual methods.

The control system of the CNC lathes is its brain, directing the movement of the tool relative to the workpiece. By automating these operations, CNC lathes enable manufacturers to produce intricate designs and maintain tight tolerances consistently.

Benefits Across Industries

Across diverse sectors, CNC lathes are transforming production lines. In aerospace, they help manufacture components that require high precision, such as engine parts. Similarly, in automotive manufacturing, CNC lathes are crucial for creating safety-critical components like brake systems.

The benefits of using CNC lathes extend beyond just the automotive and aerospace sectors. They include:

Enhanced Efficiency: Automation reduces setup times and speeds up the production process.

Consistent Quality: Automated processes ensure that each piece meets the same high standards.

Cost Reduction: Over time, reduced material waste and labor costs contribute to lower overall production expenses.

Advancements and Future Trends

Looking ahead, the future of CNC lathe technology is promising. Innovations in software, connectivity, and machine learning are leading to smarter and more integrated manufacturing solutions. These advancements are part of the broader Industry 4.0 movement, which emphasizes the integration of IoT (Internet of Things) devices into industrial processes.

Furthermore, there is a growing focus on sustainable manufacturing practices. Manufacturers are increasingly looking at ways to improve the energy efficiency of CNC machines and minimize environmental impact.

Conclusion

CNC lathes exemplify how technology can drive progress in manufacturing. By providing precision, efficiency, and flexibility, these machines are essential for many industries aiming to stay competitive in a rapidly evolving market. As we move forward, continued innovation will ensure that CNC lathes remain at the forefront of advanced manufacturing techniques.