A 2-axis multi-spindle head is a type of machine tool component that allows multiple spindles to be controlled independently along two axes. This provides increased productivity and flexibility in manufacturing processes that require multiple drilling, milling, or other machining operations to be performed simultaneously.

The key features of a 2-axis multi-spindle head include:

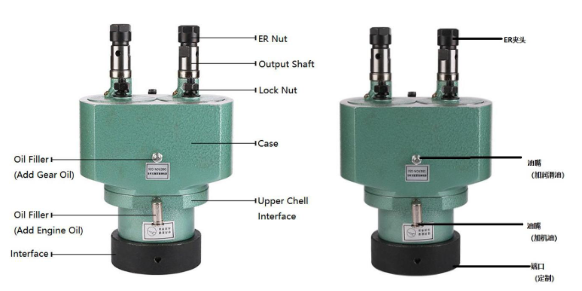

- Multiple Spindles:

- The head contains two or more individual spindles that can be controlled independently.

- This allows multiple machining operations to be performed on a workpiece at the same time.

- 2-Axis Movement:

- The spindles can move along two axes, typically the X and Y axes.

- This enables the spindles to be positioned precisely at different locations on the workpiece.

- Independent Control:

- Each spindle can be controlled independently in terms of speed, feed rate, and other parameters.

- This allows for optimization of the machining process for each individual operation.

- Compact Design:

- The multi-spindle head is designed to be compact and integrated into the machine tool, often as a modular attachment.

- This helps to minimize the footprint and increase the efficiency of the overall machining system.

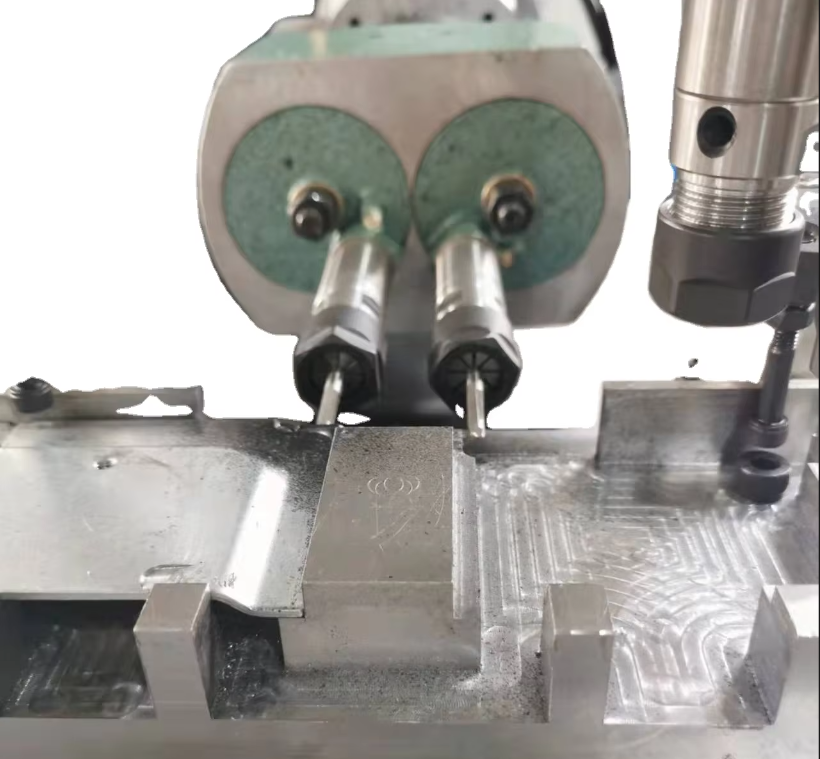

2-axis multi-spindle heads are commonly used in various manufacturing industries, such as automotive, aerospace, and electronics, where multiple drilling, tapping, or milling operations need to be performed on a single workpiece. They can be used in CNC (Computer Numerical Control) machine tools, as well as in specialized multi-spindle drilling machines.

The precise configuration and capabilities of a 2-axis multi-spindle head may vary depending on the specific application and the manufacturer’s design.

Multi-axis drills are widely used in drilling and tapping of porous parts in the machinery industry. Such as porous parts of automobiles and motorcycles: engine housings, aluminum casting housings, brake drums, brake discs, steering gears, wheel hubs, differential housings, axle heads, half-axles, axles, etc., pumps, valves, hydraulic components, solar accessories, etc. Within the processing range of the multi-hole drill, the number of spindles and the distance between the spindles can be adjusted arbitrarily, and several holes can be processed at the same time with one feed. When it works with hydraulic machine tools, it can automatically fast forward.