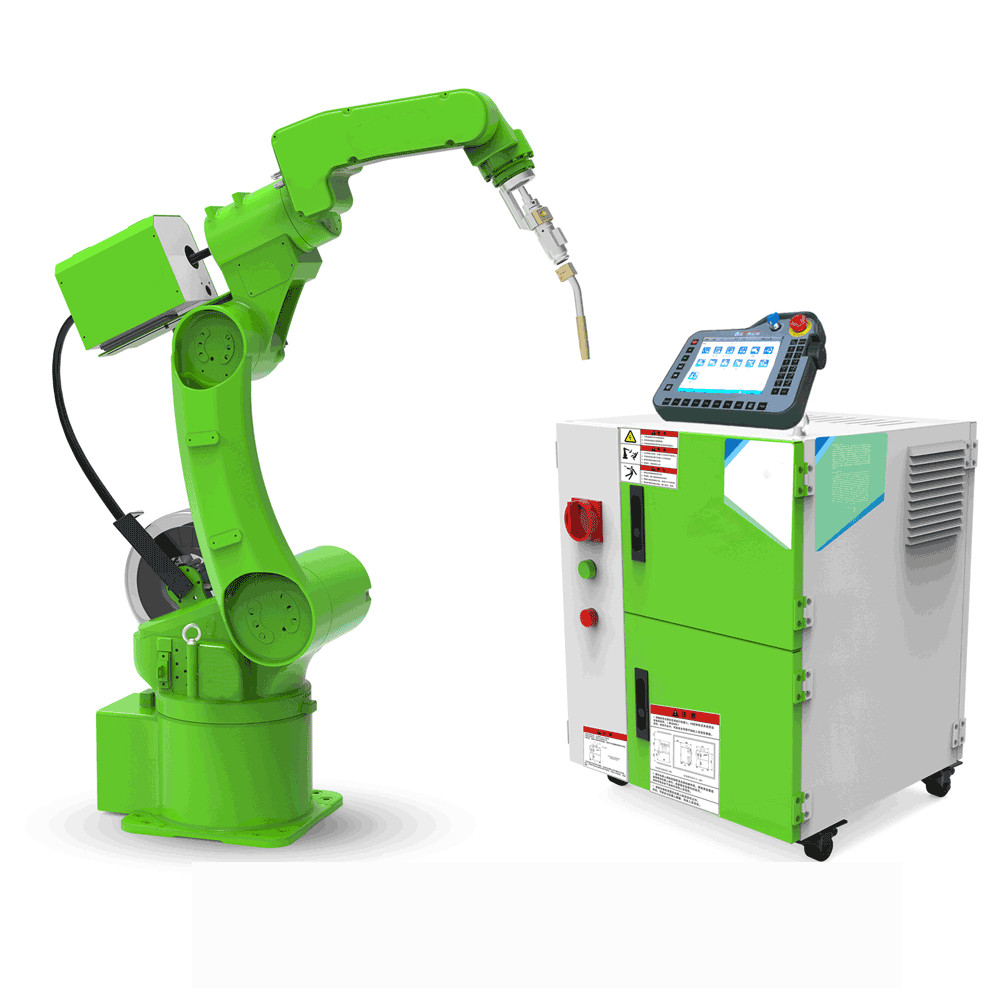

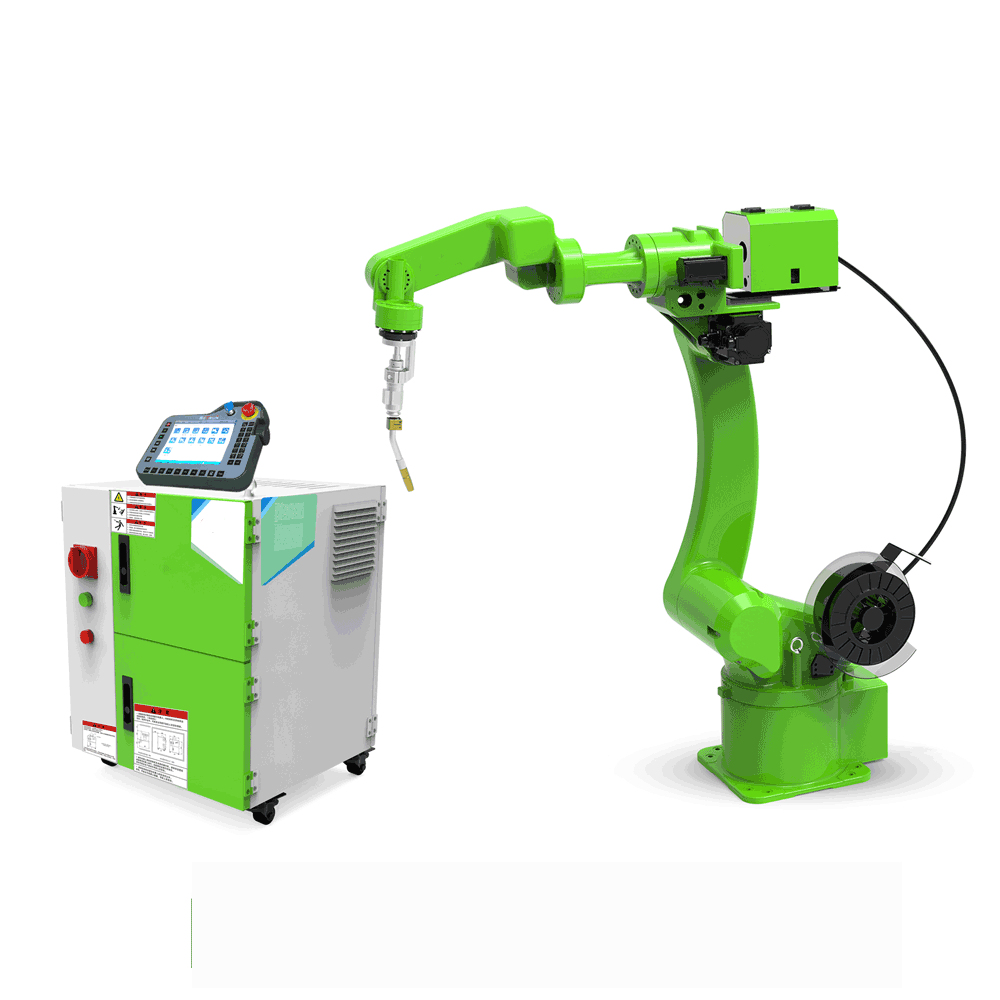

The manufacturing sector has been undergoing a profound transformation with the adoption of automation technologies. As the demand for higher efficiency and reduced labor costs continues to grow, industrial robots have become indispensable tools for modern factories. One such innovation is the LHZ1500-B-6 six-axis welding robot, a cutting-edge product made in China that is designed to enhance welding processes across a wide array of industries.

The Evolution of Welding Automation

Traditionally, welding has been a labor-intensive task requiring skilled workers and significant manual intervention. However, advancements in robotics have led to the development of machines like the LHZ1500-B-6, which can perform welding operations with greater speed, accuracy, and consistency than human operators. These robots are capable of handling repetitive tasks without fatigue, leading to increased productivity and lower defect rates.

Key Characteristics of the LHZ1500-B-6

The LHZ1500-B-6 stands out in the field of industrial robotics due to its numerous innovative features:

- Fast Movement: The robot’s ability to move swiftly helps accelerate production cycles, thereby promoting a faster rhythm in the manufacturing process.

- Sophisticated Thin Plate Technology: Equipped with advanced arc welding software, the robot can perform small line acceleration and fly arcing, ensuring smooth transitions and promoting efficiency.

- High Success Rates: The LHZ1500-B-6 is particularly adept at welding thin plates, achieving high success rates even with intricate designs.

- All-Digital Communication: The seamless integration between the robot and the welding machine ensures fast and stable performance.

- Ultra-Low Spatter Welding: Utilizing direct current (DC), the robot achieves ultra-low spatter welding even on thin plates, contributing to cleaner work environments and reduced material waste.

- Smooth Transitions: The robot ensures a gentle arc with better tension and shaping, resulting in more aesthetically pleasing weld beads.

- Enhanced Gap Tolerance: The robot can handle high tolerances for workpiece alignment errors, making it adaptable to varying conditions on the factory floor.

- Precise Wire Feeding Control: The use of an encoder for wire feeder feedback control allows for quick adjustments in response to arc fluctuations.

- Fish Scale Welding Option: An optional feature that reduces spatter and increases welding speed, further enhancing operational efficiency.

- Integrated Positioning: The built-in location function eliminates the need for additional hardware, streamlining setup procedures.

Technical Specifications

- Model Number: LHZ1500-B-6

- Condition: Brand New

- Certifications: ISO, CE, RoHS

- After-Sales Service: Online support available

- Warranty: One year warranty

- Transport Packaging: Wooden crates for secure transportation

- Specifications: Load capacity of 6kg, precision of 0.05mm, arm span of 1500mm, weighing 150kg

- Packaging: Dimensions 70.00cm * 80.00cm * 150.00cm, gross weight 300.00kg

on Industry

The introduction of the LHZ1500-B-6 represents a significant leap forward for manufacturers aiming to automate their welding processes. By offering a combination of speed, precision, and reliability, this robot helps companies achieve higher throughput and maintain consistent quality standards. Furthermore, its modular design and optional features allow for customization according to specific application requirements, making it a versatile addition to any production line.

As industries continue to evolve, embracing automation solutions like the LHZ1500-B-6 is not merely an option but a necessity for staying competitive in today’s global marketplace. This robotic welder exemplifies the ongoing efforts to integrate advanced technology into manufacturing processes, ultimately driving the industry towards greater efficiency and sustainability.