Automatic Chamfering Machine Have Its’ Own Advantages

1.Improve production efficiency: The fully automatic chamfering machine can achieve a continuous and stable production process without manual intervention, thus greatly improving production efficiency. Compared with manual operation or semi-automatic chamfering machines, fully automatic chamfering machines have significant advantages in processing efficiency.

2.Reduce labor costs: Using a fully automatic chamfering machine can reduce dependence on human resources and save labor costs. At the same time, because the fully automatic chamfering machine is simple to operate and has a short training cycle, it also helps companies improve response speed and flexibility.

3.Improve product quality: The machine adopts a digital control system, which can ensure the accuracy and consistency of chamfering and effectively avoid the impact of human factors on product quality. This helps to improve product reliability and stability and meet the needs of high-precision processing.

4.Reduce tool loss: It has an automatic tool changing function and can change different tools according to the requirements of the workpiece. This avoids possible errors and tool wear caused by manual tool replacement, extends tool life, and reduces maintenance costs.

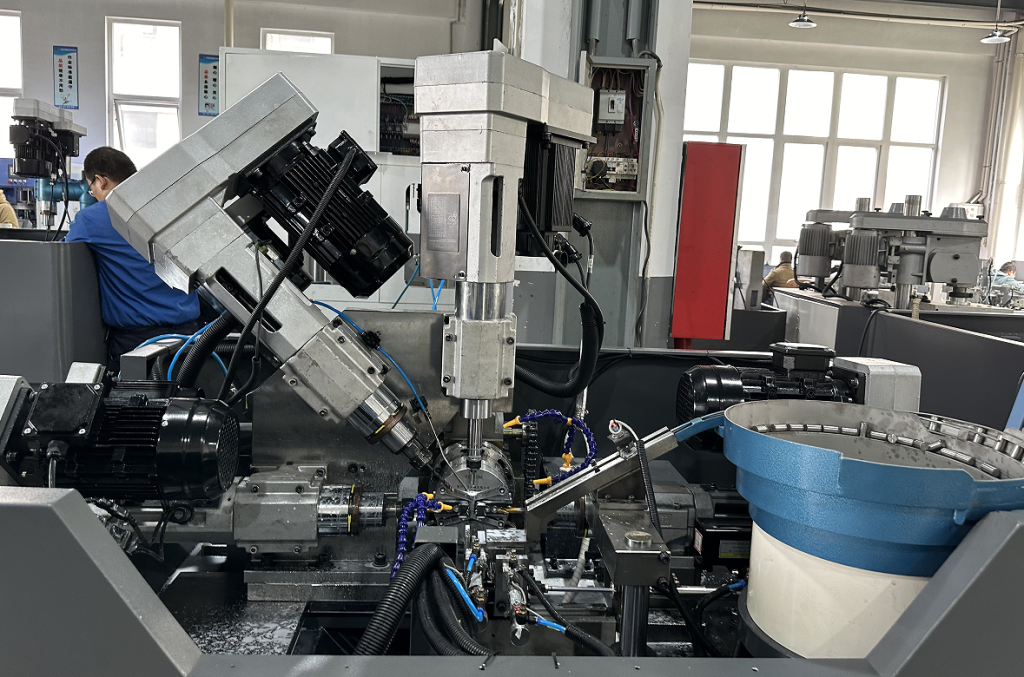

5.Advanced technology: It is controlled and operated by a PLC system, and the operation is input through a touch screen program. It is highly intelligent and easy to operate and reliable. In addition, the fully automatic chamfering machine has a compact structure and reasonable design, uses a cast machine head and a sturdy and durable bed, and the spindle independent machining center has reliable processing performance.

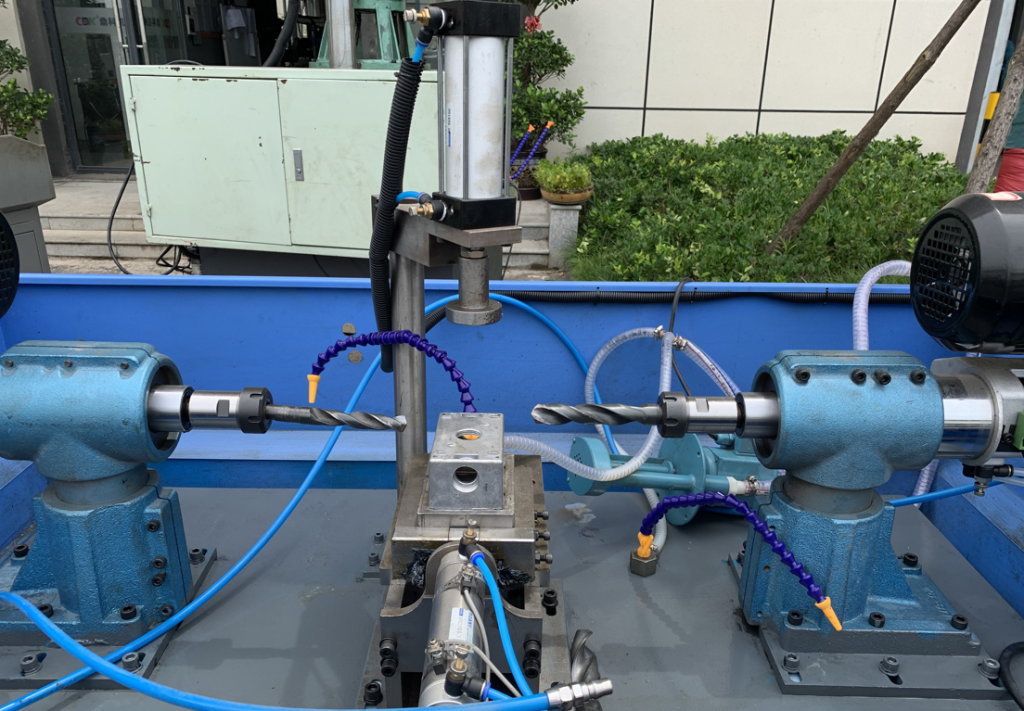

6.Can meet a variety of chamfering requirements: It uses CNC standard tools and can automatically complete various chamfering requirements such as C angles, R angles, arc angles, bevels, steps, etc. This meets the chamfering needs of different industries and products, and improves the adaptability and flexibility of the equipment.

7.High degree of automation: It has a variety of automation functions, such as automatic feeding, automatic clamping, automatic chamfering, automatic processing, etc. These functions not only improve production efficiency and quality, but also reduce operator labor intensity and operating errors.

In summary, the fully automatic chamfering machine has the advantages of improving production efficiency, reducing labor costs, improving product quality, reducing tool wear, being technologically advanced, able to meet a variety of chamfering requirements, and having a high degree of automation. For companies and manufacturers that need to perform metal chamfering processing, choosing a fully automatic chamfering machine is a very wise choice.