1. Drilling and tapping of the work piece are completed manually in 5 processes. The work piece rotates at different stations, which is inefficient.

2. The tooling is manually clamped, and each station can only process one piece at a time.

3. Aluminum chips need to be cleaned manually, and waste aluminum chips are difficult to recycle.

4. The processing time of a work piece depends on labor efficiency.

After transformation:

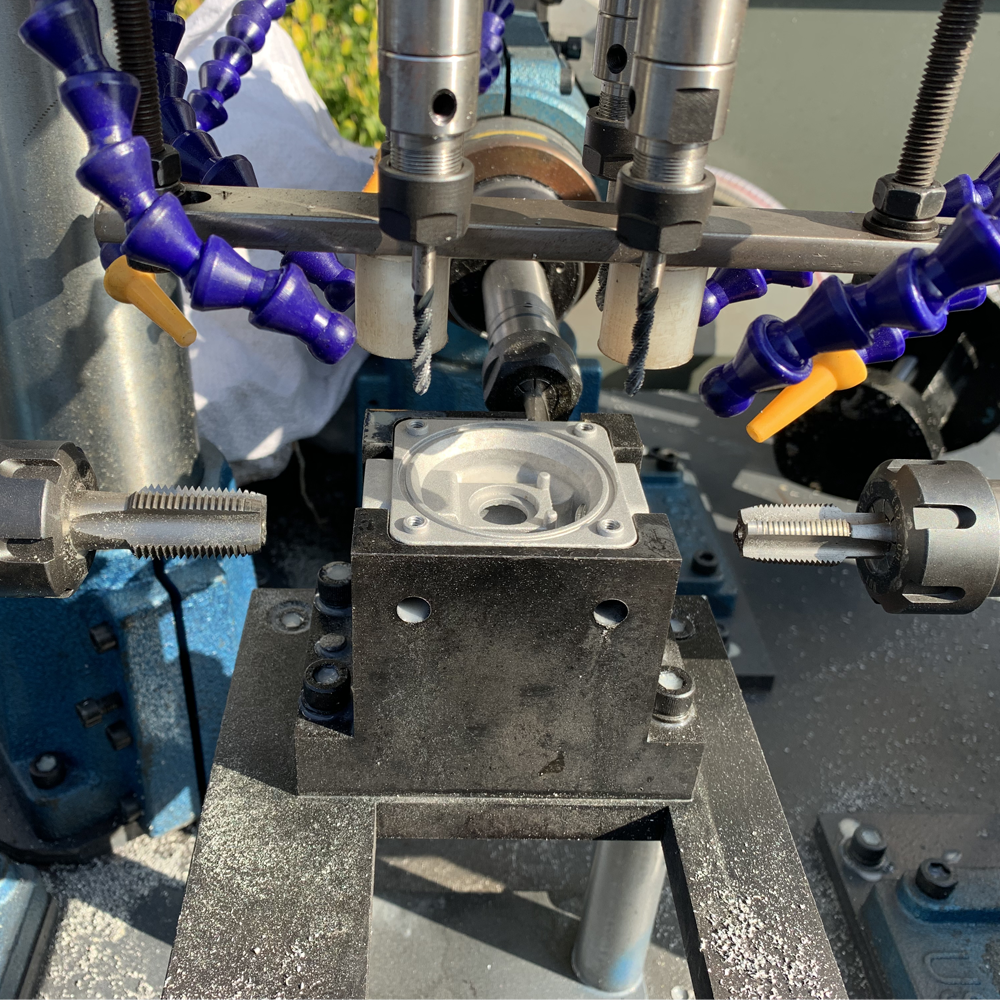

1. The drilling and tapping of the work piece are completed in 5 processes. There is only manual loading and unloading between the processes, and the other steps in each process are completed automatically.

2. The tooling adopts pneumatic clamping. Just turn on the button and the work piece will be automatically positioned and clamped. Each workstation can clamp 2 pieces at the same time.

3. The equipment has the function of automatically cleaning aluminum chips from the work piece, processing the aluminum chips, and filtering them back with the cutting fluid.

4. Time beat, each workstation takes about 60 seconds to complete a single pump.

Advantages of automation equipment:

1. The use of automated equipment can reduce manpower and reduce product production costs.

2. Can increase production capacity.

3. Reliable automated products are easier to manage than manual ones.

4. It can effectively improve product quality, and product consistency can be effectively improved through the use of automated equipment.

5. Enhance the company’s compet