Description

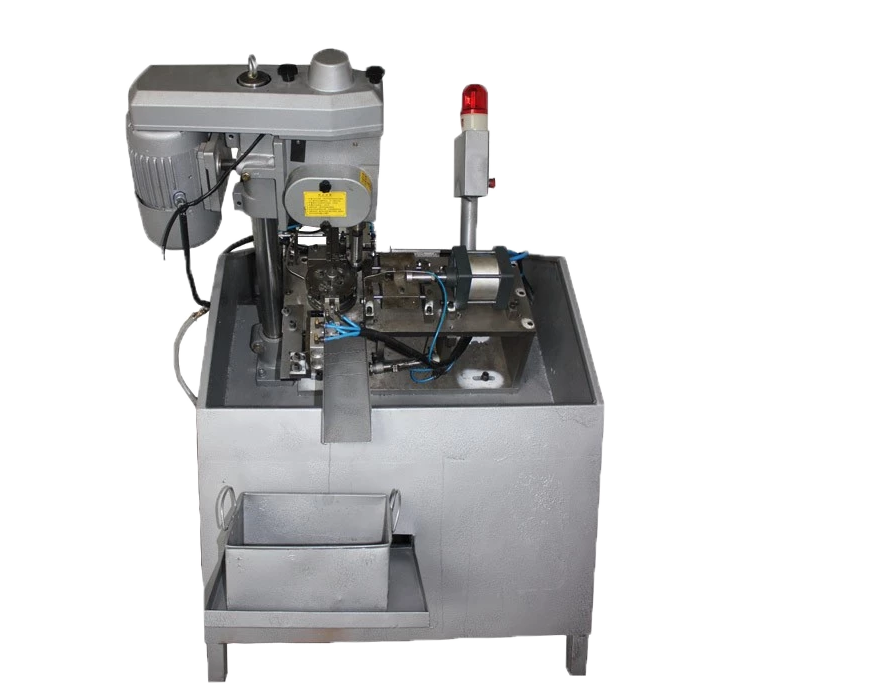

Nut tapping machine is a kind of mechanical processing equipment that processes internal threads, screws or threads on the inner side of the holes of nuts, flanges and other parts with various specifications of through holes or blind holes.

Nut tapping machine is also called nut tapping machine or automatic nut tapping machine or fully automatic nut tapping machine.

The fully automatic tapping machine realizes fully automatic feeding through a vibrating plate or a feed guide. It controls the tapping speed and depth through pneumatic automatic feeding and PLC to complete automatic feeding, automatic tapping processing, and automatic unloading.

By adjusting the pneumatic feed speed and time, tapping speed adjustment and true unmanned production can be realized, manpower can be saved, multiple heads can work together, and work efficiency and labor costs can be greatly improved.

Features

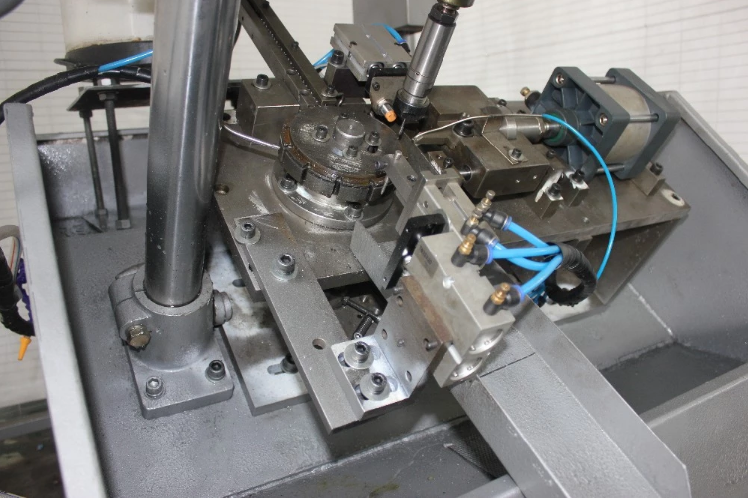

This machine has a reasonable structure and multiple heads working at the same time, which greatly increases the production speed.

For threaded hole processing of electrical connectors—a single head can reach 3,000 hole tapping operations per hour. It is easy to operate, safe, reliable, and energy-saving. It is suitable for nuts. , tapping processing of electronic connectors, fasteners, fasteners, etc.

Principle

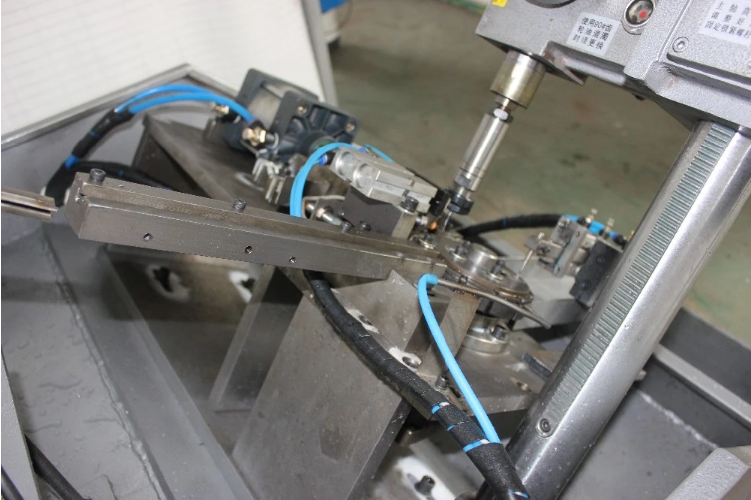

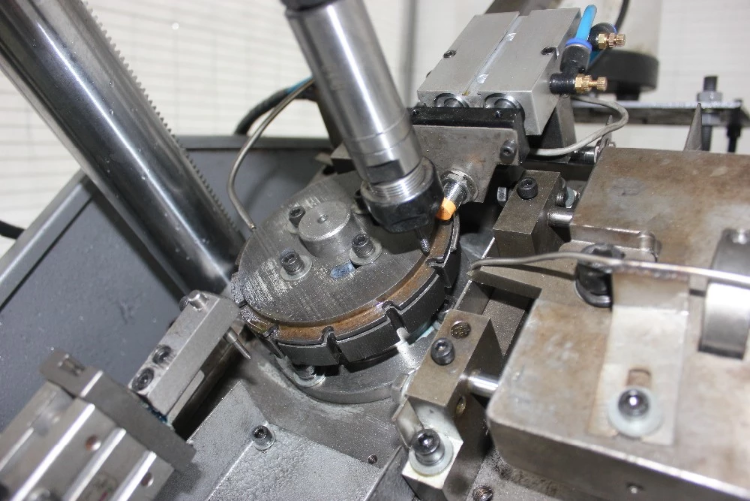

The pneumatic tapping machine is driven by compressed air, which is safe, fast and efficient. It has small air pressure and air volume (0.3-0.8mpa) and large torque output. It can tap various steel, iron, copper, aluminum, plastic and other materials; barrel with an entrainment overload protection device.

The tapping is less damaged and the thread accuracy is high.The operation is simple and light, requiring no experience and strength at all. The workpiece does not require positioning devices or movement and the working area is extremely large (within the radius of 100-2000mm).

The positioning is fast and the cutting speed is high, increasing the production volume through holes or blind holes. Wire tapping will not break, vertical, ( Universal) angles can be tapped. Large processing range: (M3-M24). Product and service life guaranteed.

Main advantages:

1.Automatic feeding, tapping and blanking are completed at the same time.

2.Use ratchet mechanical device for accurate positioning to ensure accuracy.

3.Various specifications, customization accepted.

Single head nut tapping machine

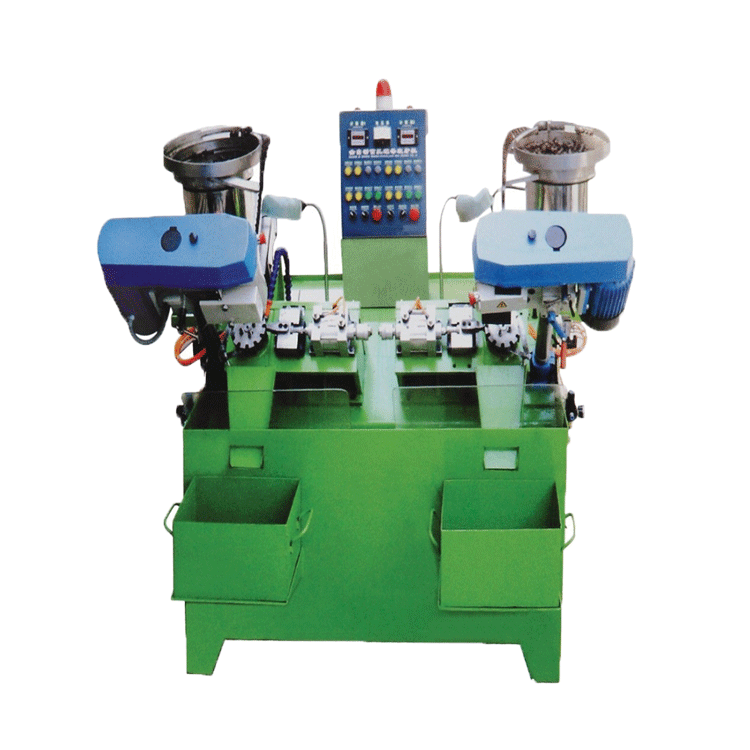

Double head nut tapping machine

Application: