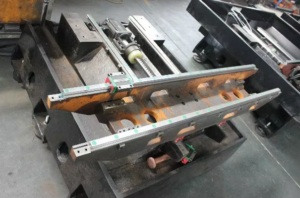

Understanding the cost of CNC lathe machine investments goes beyond price tags. For manufacturers and workshops, long-term value hinges on durability, versatility, and reduced operational waste—qualities embodied in our Heavy Drilling And Tapping Center Series Lathe Machine V-600.

Why the V-600 Reduces Hidden Costs

Traditional CNC lathes often incur expenses from frequent maintenance, inefficiency, and limited adaptability. The V-600 tackles these challenges with proprietary engineering:

- Patented Vibration-Dampening Bed: Reduces tool wear by 40% and extends machine lifespan.

- Multi-Function Headstock: Integrates drilling, tapping, and turning operations in one cycle, slashing production time by 35%.

- Smart Speed Control: Auto-adjusts spindle speeds (50–4,500 RPM) to optimize cutting for materials like steel, aluminum, or composites.

- Modular Tooling System: Swap tools in seconds without recalibration, minimizing downtime.

- All-Terrain Durability: Reinforced cast-iron construction withstands 24/7 industrial use.

Applications That Drive ROI

The V-600’s hybrid design bridges precision machining and heavy-duty tasks:

- High-Volume Fabrication: Produce engine shafts, hydraulic fittings, or aerospace components with ±0.002mm tolerance.

- Custom Prototyping: Rapidly adjust feed rates (0.05–0.5mm/rev) for low-batch experimental parts.

- Multi-Axis Drilling: Execute angled taps and deep-hole boring in a single setup.

For workshops battling rising labor and energy costs, automation isn’t optional—it’s essential.

Optimize Your Cost of CNC Lathe Machine Investments Now

The V-600 isn’t just equipment—it’s a profit multiplier. With a 3-year warranty and lifetime technical support, we ensure your operations stay competitive. Request a free productivity audit today to calculate your potential savings.