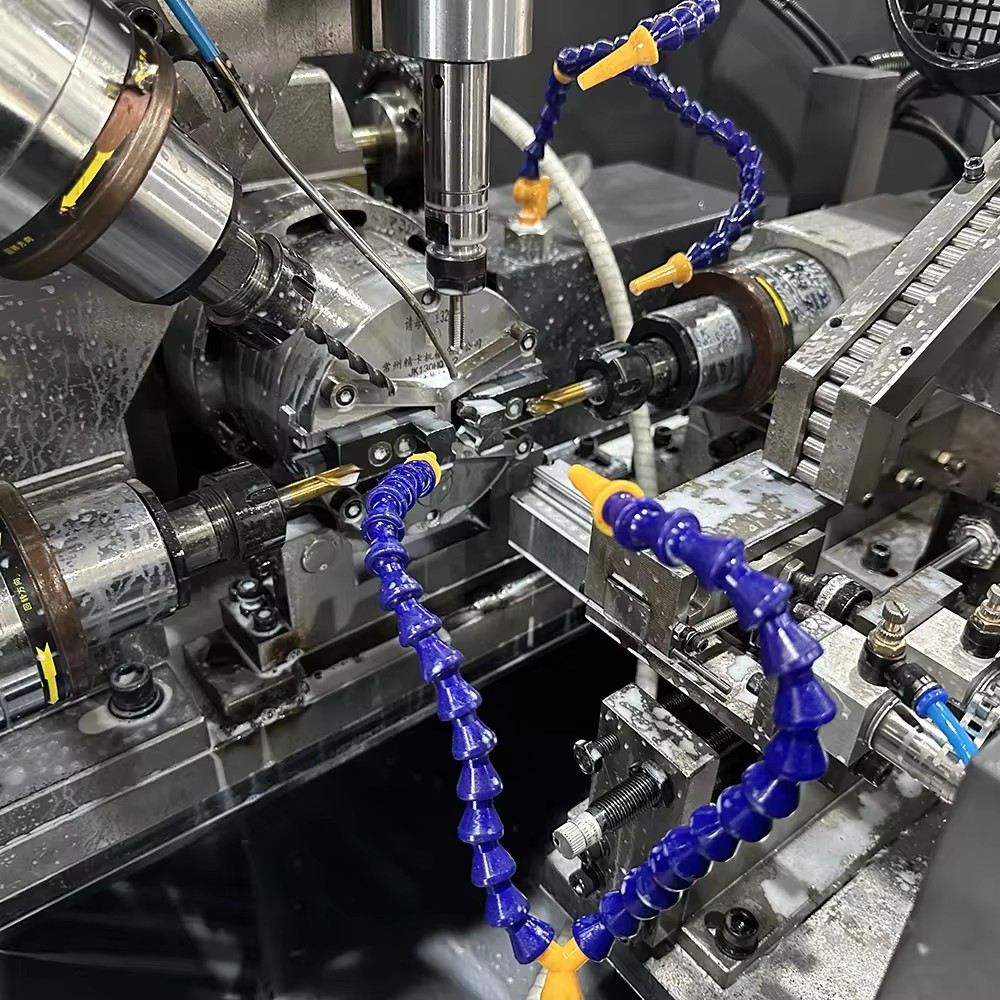

Drilling tapping machine act the role of automotive motorcycle part

1. Precision processing

Drilling and tapping machines can accurately process holes of different shapes and materials, and process the required threads at the hole mouth. This precision is crucial to the manufacture of automotive and motorcycle parts, because automotive and motorcycle parts often need to meet strict dimensional and tolerance requirements. The high-precision processing capabilities of drilling and tapping machines can ensure the accuracy and reliability of accessories.

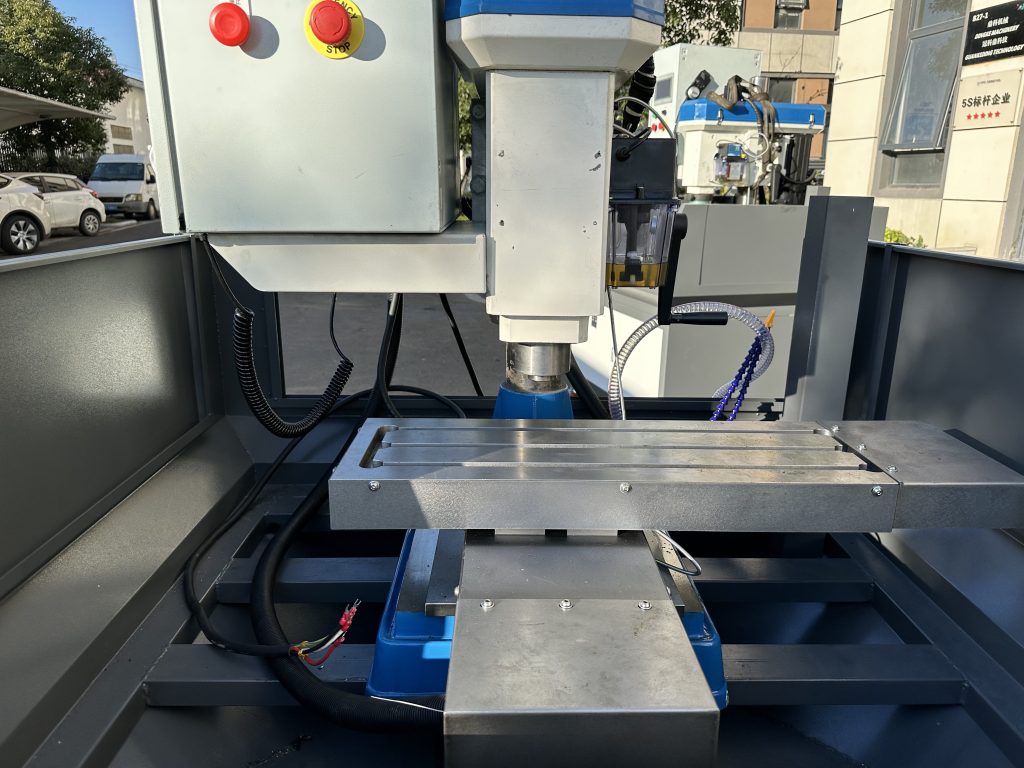

2. Improve production efficiency

Drilling and tapping machines have the advantages of stable processing, easy operation, and fast speed, which can greatly improve production efficiency. In the manufacturing process of automotive and motorcycle parts, drilling and tapping machines can quickly complete the hole processing and thread processing of a large number of accessories, reducing production time and cost.

3. Guarantee product quality

Drilling and tapping machines have high processing accuracy, higher residual finish, and more complex processing technology, which is conducive to fixing external threads on materials. These advantages enable drilling and tapping machines to ensure product quality and reduce defective and scrap rates in the manufacture of automotive and motorcycle parts.

4. Adapt to a variety of materials

Drilling tapping machine can adapt to the processing needs of a variety of materials such as metal, wood, and plastic. In the manufacturing of auto parts, different parts may use different materials. The wide adaptability of drilling and tapping machines enables it to meet the processing needs of various materials.

5. Reduce processing costs

Drilling and tapping machines have less wear, can protect materials, avoid crystallization strain, and ensure less deformation during processing. These advantages enable drilling and tapping machines to reduce material loss and processing costs during processing. In addition, drilling and tapping machines can also have better drilling accuracy and quality according to the positioning and positioning requirements of different materials and accessories, thereby further reducing processing costs.

In summary, drilling tapping machine play an important role in the manufacturing of auto parts. Its advantages such as precise processing, improved production efficiency, guaranteed product quality, adaptability to a variety of materials and reduced processing costs make it an indispensable processing equipment in the manufacturing of auto parts.