Drilling Tapping Machine Wide Use In Die Casting Industry

Application:

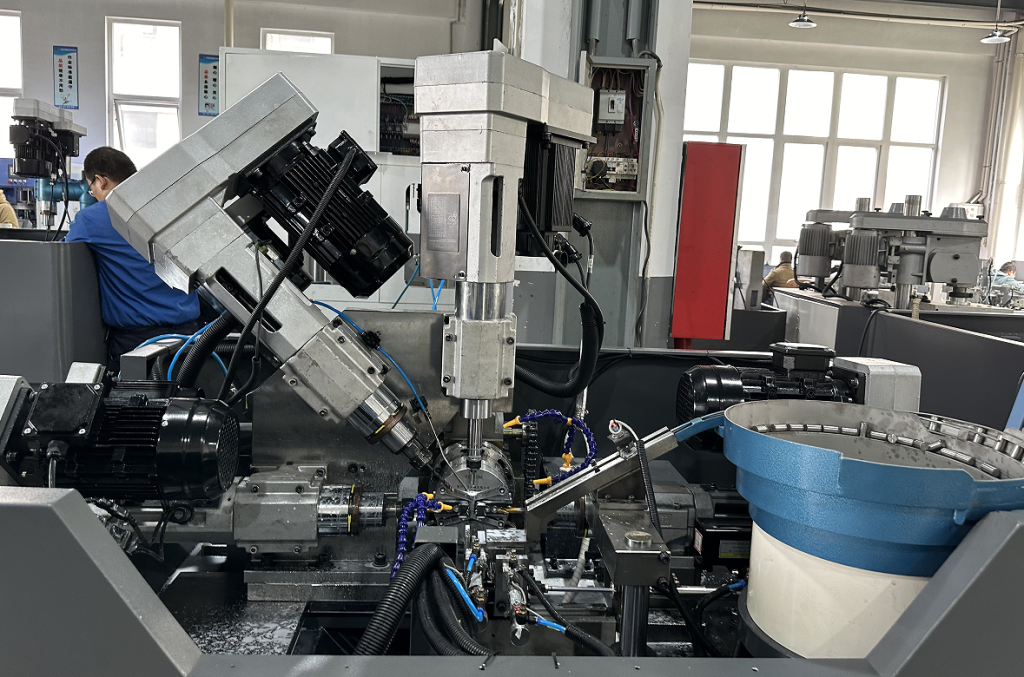

1.Processing efficiency: The die casting industry needs to process a large amount of metal materials, such as aluminum, copper, steel, etc., to manufacture various parts. The drilling and tapping machine can automatically complete hole cutting processing such as dotting, drilling, chamfering, tapping, etc., and the product can be clamped once to complete multiple processes, which greatly improves production efficiency.

2.Processing accuracy: The die casting industry has very high requirements for product accuracy and reliability. The drilling and tapping machine has the characteristics of high precision and high speed, which can ensure that the processed products meet strict accuracy requirements. At the same time, it can also realize automatic operation through programming, avoiding errors in manual operation and improving production accuracy.

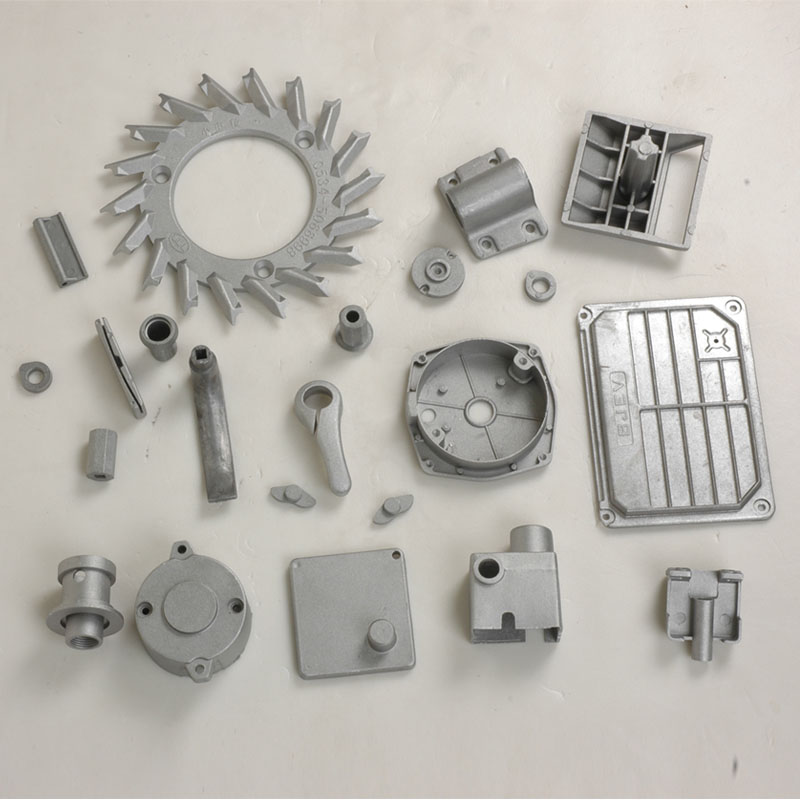

3.Application range: Die castings are widely used in the fields of automobiles, motorcycles, home appliances, medical care, photovoltaics and other industries. The application of drilling and tapping machines in these industries is also very common, and can be used to process various die castings, such as engine air box, cylinder head, piston, intake manifold and other parts.

4.Reduce costs: The drilling and tapping machine can realize fully automated production, reduce dependence on labor, and reduce labor costs. At the same time, its high efficiency and high precision can also reduce scrap rate and rework rate, further reducing production costs.

In summary, drilling tapping machine have broad application prospects in the die-casting industry. They can improve production efficiency, processing accuracy and reduce costs, providing strong support for the development of the die-casting industry.

Importance:

1.Improve production efficiency: The drilling and tapping machine can realize automated, high-precision drilling and tapping operations, greatly improving production efficiency. In the production process of die-casting parts, many parts need to be drilled and tapped, and the drilling and tapping machine can complete these operations quickly and accurately, reducing the time and labor cost of manual operation and shortening the production cycle.

2,Ensure product quality: The drilling and tapping machine has the characteristics of high precision and high stability, which can ensure the dimensional accuracy and position accuracy of drilling and tapping. In the die-casting industry, product quality is crucial, and high-precision drilling and tapping can ensure the assembly accuracy and reliability of parts, thereby improving the quality and performance of the entire product.

3,Reduce scrap rate and rework rate: Due to the high precision and automation characteristics of the drilling and tapping machine, the scrap rate and rework rate caused by human operation errors can be reduced. This can not only reduce waste in the production process, but also improve production efficiency and reduce costs.

4.Flexibility and adaptability: The drilling and tapping machine can be programmed and adjusted according to different product requirements to adapt to the processing of die-casting parts of different specifications and shapes. This flexibility and adaptability enables the drilling and tapping machine to cope with the diverse production needs in the die-casting industry, and improves the flexibility and adaptability of the production line.

5.Safe production: The automated operation of the drilling and tapping machine reduces the risk of manual operation and improves the safety of the production process. At the same time, it can also avoid industrial accidents caused by human operating errors, providing a strong guarantee for the safe production of the enterprise.

In summary, the importance of drilling tapping machine to the die-casting industry is mainly reflected in improving production efficiency, ensuring product quality, reducing scrap and rework rates, improving the flexibility and adaptability of production lines, and ensuring safe production. These advantages make drilling and tapping machines one of the indispensable and important equipment in the die-casting industry.