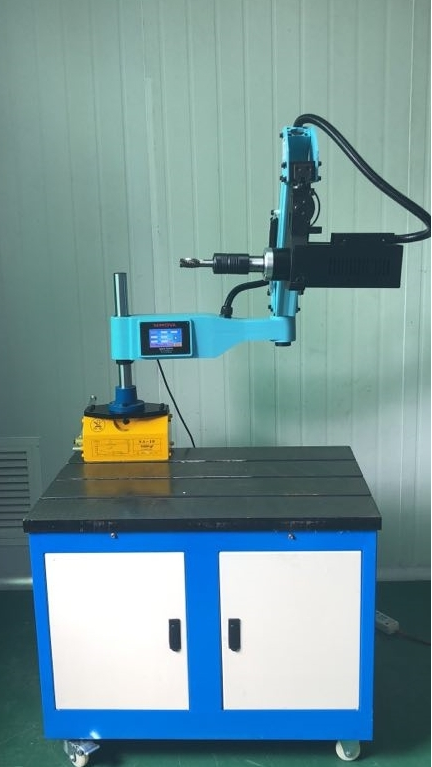

Electric Tapping Machine Change Your Life With its Own Advantages

Operation:

(1) Plug in the power socket (220V);

(2) Open the control cabinet of the electric tapping machine;

(3) Adjust the speed according to the touch screen of the control cabinet;

(4) Adjust the range of tapping required, such as 2000-3000 rpm for tapping 3-16, 800-1600 rpm for tapping 18-24, and 500-800 rpm for tapping 30.

(5) There is a black handle on the servo motor with two switches, the upper one is for reverse rotation and the lower one is for forward rotation.

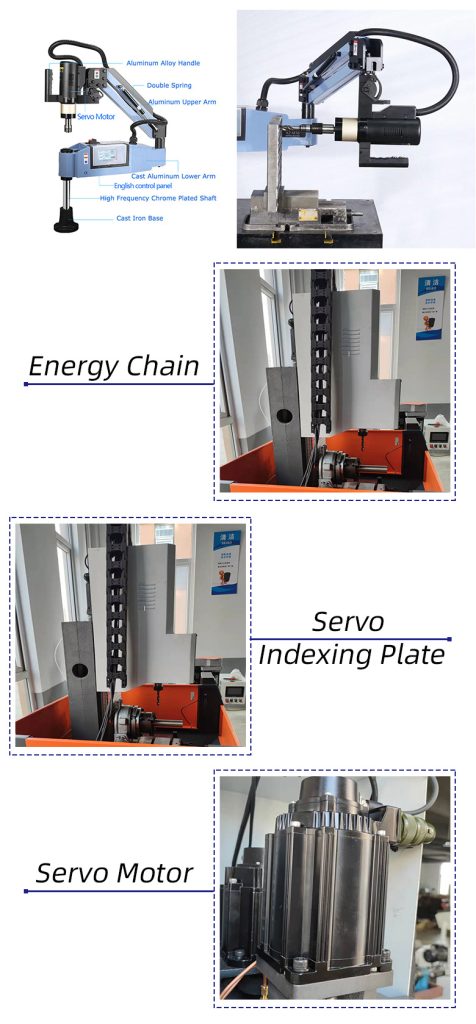

Advantages:

1. This machine adopts servo drive control with intelligent torque protection. It replaces the limitations of traditional lathes, drilling machines or manual tapping.

2. Advanced mechanical design, multiple processes use mold castings, strong overall rigidity, durable and non-deformed, beautiful appearance.

3. The high-definition touch screen is simple and flexible to operate, and can achieve vertical and horizontal work, rapid positioning and accurate processing for complex and bulky workpieces.

4. This machine uses three modes of tapping: automatic mode, manual mode, and deep hole mode (vibration mode) can be selected. The tapping speed range can reach 0-312 (rpm) stepless speed regulation, so that different speeds can be selected when tapping different materials to improve tapping efficiency.

5. The automatic mode can effectively control the tapping depth, without the need to operate buttons, and is automatically controlled by the depth controller.

Rapid repeated positioning, fast tapping speed, and high production efficiency.

6. Product applicable workpiece materials:

Electric tapping machine can easily tap metal materials such as lead, copper, steel, cast iron, pig iron, 45 steel, mold steel, ace material, etc.

Application:

Electric tapping machine are suitable for all machinery manufacturing industries, machine tools, mold machinery, plastic machinery, printing machinery, packaging machinery manufacturers, engineering machinery, automobile and motorcycle parts, aircraft engines, locomotives, tobacco machinery and general machinery industries.

Features

(1) Stable torque and long life;

(2) Rapid repeated positioning, fast cutting speed and high production efficiency;

(3) The safety torque collet ensures less damage to the tap; the through-hole and blind-hole taps are continuous and the tapping accuracy is high;

(4) The working range is large and heavier workpieces do not need to be moved;

(5) Simple operation, light weight, high efficiency and low work intensity, suitable for various light and heavy operations;

(6) Universal positioning to achieve horizontal tapping;

(7) With automatic lubrication function, it can realize automatic spraying of tapping oil and automatic lubrication of taps, so as to achieve thread-fitting and higher efficiency;

(8) The verticality error of the machine body is <0.05mm.