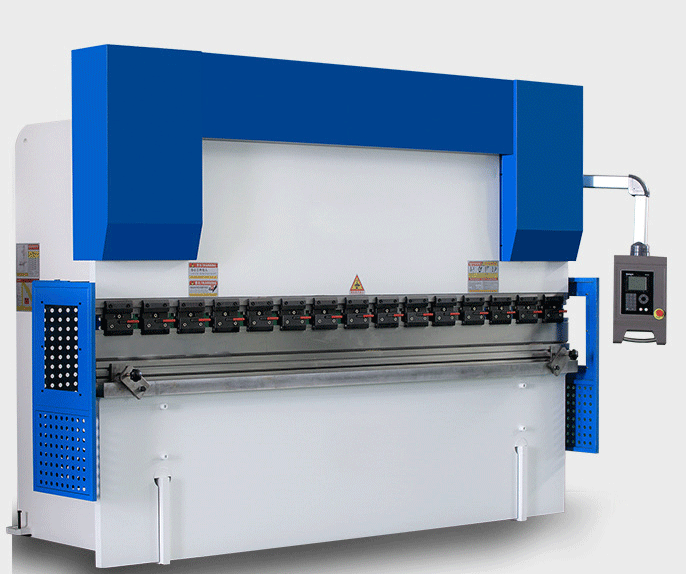

Features of bending machine

Structural composition:

Body: Usually welded from rigid steel plates, it provides a stable support structure for the entire machine tool and ensures the accuracy and stability of the machine tool.

Operation system: It consists of a control panel, buttons and joysticks, and the control system is used to achieve precise control of the movement and working parameters of the bending machine.

Transmission system: It is responsible for transmitting the power of the motor to each moving part. Hydraulic transmission or mechanical transmission can be used. Hydraulic transmission has the advantages of high stability and precision, while mechanical transmission has the advantages of simple structure and low cost.

Workbench: It is used to place and fix metal materials, usually composed of a front baffle plate, a rear baffle plate and a pressure plate to ensure the precise processing of metal materials.

Functional features:

Multi-function: It can bend metal materials of different types and thicknesses, such as steel plates, aluminum plates, etc. By adjusting the working parameters and molds, bending of different shapes can be achieved.

High precision: The use of precise control systems and transmission systems can achieve high-precision bending of metal materials. For example, the positioning accuracy of the rear baffle and the slider dead baffle can reach ±0.02mm.

High efficiency: Continuous production is achieved through automated control, which greatly improves production efficiency. The CNC bending machine has a multi-step programming function, which can realize multi-automatic operation and complete one-time processing of multi-step parts.

Flexibility: It can be adjusted and changed according to different processing requirements to realize a variety of bending methods, such as V-bending, U-bending, bending, etc. It can also be equipped with different molds to adapt to the processing of workpieces of different shapes and sizes.

Technical features:

Programmable control: The new generation of bending machines adopts an advanced programmable control system to store processing data in the computer and adjust the processing parameters through the control system.

Energy saving and environmental protection: It adopts advanced motors, hydraulic systems and other equipment, with the characteristics of low noise, high efficiency and low energy consumption. During the material processing process, no secondary pollution will be generated, protecting the environment.

Simple operation: The control panel is simple and easy to use, and the operator only needs simple training to use the equipment proficiently.

Other advantages:

The bending machine mold has the characteristics of direct bending, no splicing, no grooving, no welding rods, etc. The appearance of the corner is beautiful and leak-proof. At the same time, the processing speed is fast, the surface of the corner treatment is beautiful, and the strength is high.

The CNC bending machine has a one-button quick bending customization function, which improves production efficiency and product quality.

In summary, the bending machine plays an important role in modern manufacturing with its stable structure, diverse functions, advanced technology and easy operation, and is widely used in automobile, aerospace, machinery manufacturing and other fields.