Lathe machine mainly uses a turning tool to turn a rotating workpiece. Drills, reamer drills, reamers, taps, dies and knurling tools can also be used on the lathe for corresponding processing.

1. Ordinary lathe machine

It has a wide range of processing objects, a large adjustment range of spindle speed and feed rate, and can process the inner and outer surfaces, end faces and inner and outer threads of workpieces. This type of lathe is mainly operated manually by workers, with low production efficiency, and is suitable for single-piece, small-batch production and repair workshops.

2. Turret lathe and rotary lathe

The turret tool holder or return wheel tool holder that can hold multiple tools can be used by workers to complete multiple processes in one clamping of the workpiece, which is suitable for batch production.

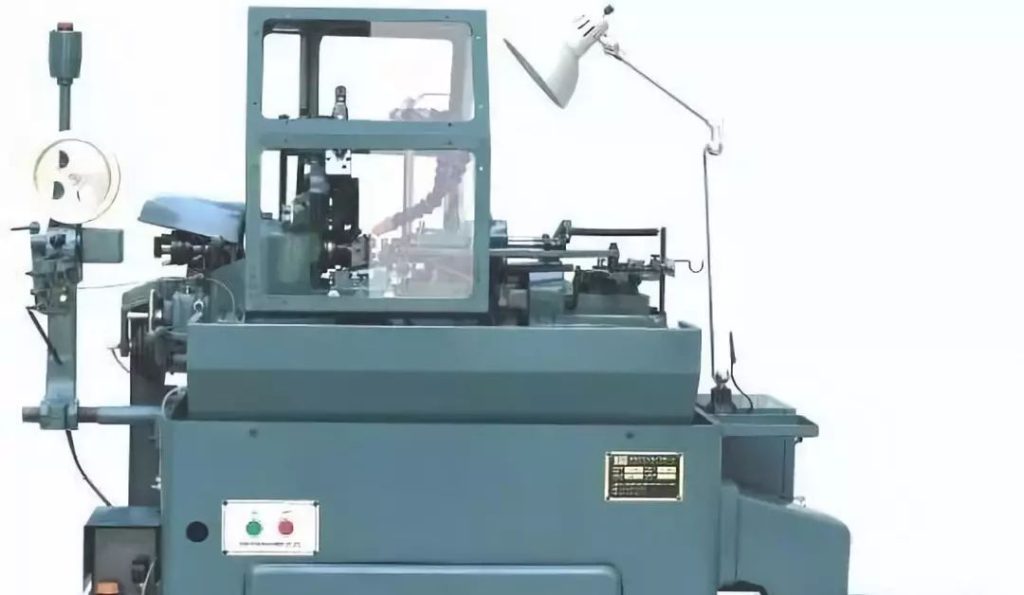

3. Automatic lathe machine

It can automatically complete the multi-process processing of small and medium-sized workpieces according to a certain procedure, can automatically load and unload materials, and repeatedly process a batch of the same workpieces, which is suitable for large-scale and mass production.

4. Multi-tool semi-automatic lathe machine

It is divided into single-axis, multi-axis, horizontal and vertical. The layout of the single-axis horizontal lathe is similar to that of the ordinary lathe, but the two sets of tool holders are installed in front of and behind the spindle or above and below, which are used to process disks, rings and shaft workpieces. Its production efficiency is 3 to 5 times higher than that of the ordinary lathe.

5. Copy lathe machine

It can imitate the shape and size of the template or sample and automatically complete the processing cycle of the workpiece. It is suitable for small batch and batch production of workpieces with more complex shapes. The productivity is 10 to 15 times higher than that of ordinary lathes. There are multiple tool holders, multi-axis, chuck type, vertical type and other types.

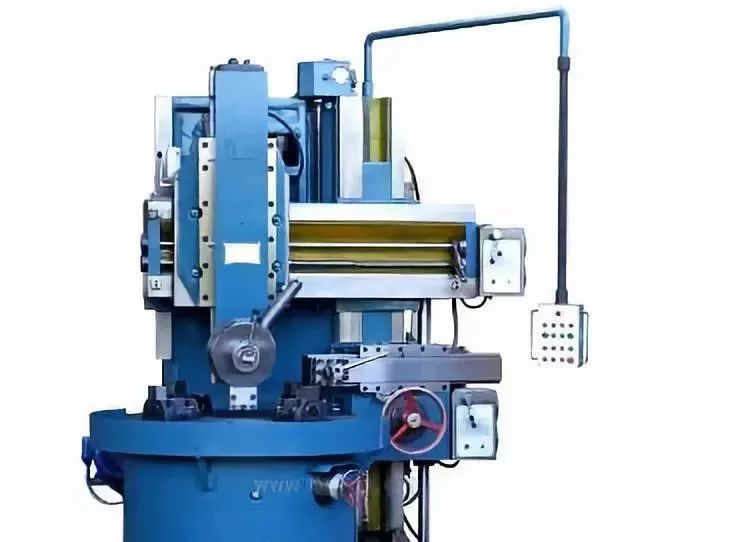

6. Vertical lathe machine

The spindle is perpendicular to the horizontal plane, the workpiece is clamped on the horizontal rotary table, and the tool holder moves on the crossbeam or column. It is suitable for processing larger, heavier workpieces that are difficult to install on ordinary lathes. It is generally divided into two categories: single column and double column.

7. Shovel lathe machine

While turning, the tool holder periodically reciprocates radially, which is used to shovel the tooth surface of milling cutters, hobs, etc. It is usually equipped with a shovel grinding attachment, and the tooth surface is shoveled by a small grinding wheel driven by a separate motor.

8. Special lathe machine

A lathe used to process specific surfaces of a certain type of workpiece, such as crankshaft lathes, camshaft lathes, wheel lathes, axle lathes, roll lathes and ingot lathes.

9. Combined lathe machine

It is used for turning processing, but after adding some special parts and accessories, it can also be used for boring, milling, drilling, inserting, grinding and other processing. It has the characteristics of “one machine with multiple functions” and is suitable for repair workers on engineering vehicles, ships or mobile repair stations.