For manufacturers and engineers, understanding the components of CNC lathe machines is key to unlocking peak performance. Each part’s design and durability directly impact productivity, precision, and operational costs. The Heavy Drilling and Tapping Center Series Lathe Machine V-800 exemplifies how advanced engineering of components of CNC lathe machines drives efficiency in high-stakes industries. Discover how its architecture sets new benchmarks.

Critical Components of CNC Lathe Machines Explained

The components of CNC lathe machines work synergistically to transform raw materials into precision parts. The V-800 elevates this synergy through purpose-built design:

Vibration-Absorbing Bed:

- Material: High-grade cast iron minimizes chatter during heavy drilling or tapping, ensuring surface finishes within 0.2µm Ra.

- Function: Acts as the machine’s foundation, stabilizing operations even at 3,500 RPM spindle speeds

Multi-Tasking Headstock:

- Spindle Range: 50–3,500 RPM with automatic speed adjustment, handling materials from soft plastics to hardened steel.

- Motor Integration: Direct-drive motors eliminate belt slippage, boosting torque by 25% for demanding cuts.

Adaptable Tailstock:

- Tool Compatibility: Supports live tooling for drilling and threading, enabling complex operations without repositioning.

- Hydraulic Clamping: Secures workpieces up to 150mm in diameter with zero deflection

Precision Carriage and Cross Slide:

- Linear Guideways: Enable smooth, frictionless movement for tolerances within ±0.003mm.

- Quick-Change Tool Posts: Swap tools in seconds, reducing downtime between jobs

Smart Feed Mechanism:

- Automated Control: Programmable feeds optimize chip load and cutting speed, slashing cycle times by 30%.

Applications Demanding Superior Components

- Aerospace: Machine turbine shafts with zero runout, meeting AS9100 standards.

- Automotive: Produce high-volume engine components with repeatable accuracy.

- Medical Device Prototyping: Craft intricate surgical tools using micro-turning capabilities.

Why the V-800’s Components Outperform

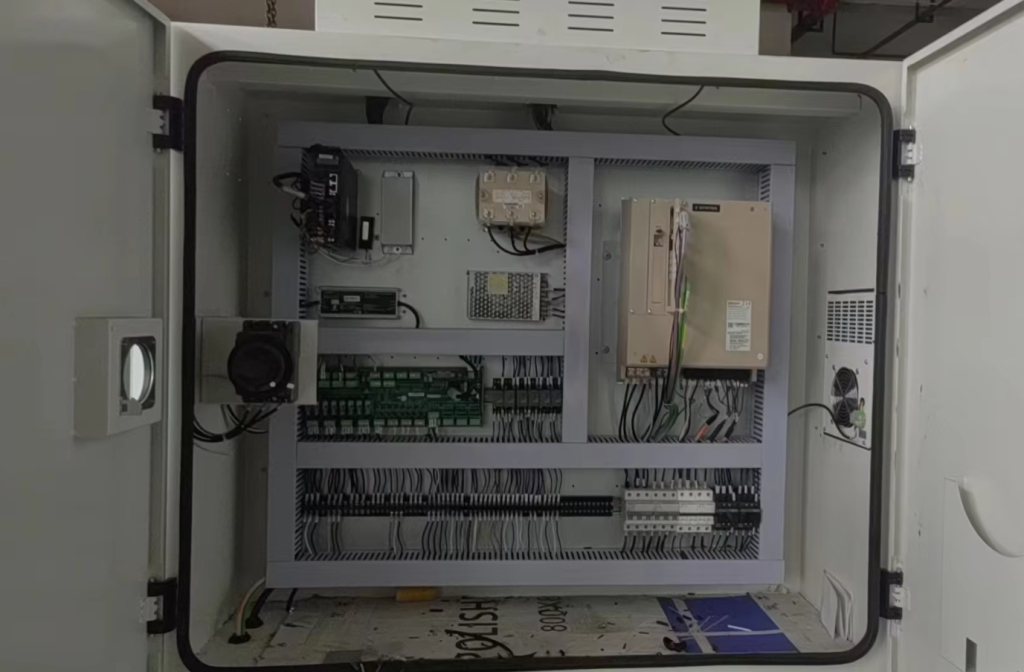

Unlike generic components of CNC lathe machines, the V-800 integrates innovations that redefine reliability:

- IP54-Rated Enclosures: Protect against coolant ingress and metal dust in harsh workshops.

- Modular Upgrades: Retrofit IoT sensors for predictive maintenance or integrate cobots for lights-out production.

- Energy Recovery Systems: Convert braking energy into reusable power, cutting energy costs by 18%.

ROI-Driven Engineering

Investing in the V-800’s components of CNC lathe machines delivers measurable returns:

- 40% Faster Setup: Automated tool alignment and preset programs reduce idle time.

- 50% Longer Tool Life: Precision alignment minimizes edge wear on cutting tools.

- 20% Lower Scrap Rates: Vibration damping and real-time corrections ensure first-pass accuracy.

Elevate Your Production Line Today

Don’t let outdated components of CNC lathe machines hold back your potential. Explore the Heavy Drilling and Tapping Center Series Lathe Machine V-800 and experience how its engineered excellence transforms manufacturing. Contact us for a customized demo, bulk order discounts, or technical consultations—equip your workshop with components built to dominate precision machining.