Milling Chuck: A Key Component in Precision Machining

In the modern manufacturing industry, efficiency and precision are essential for production processes. As a critical component that connects the machine tool spindle to the cutting tool, the Milling Chuck plays a vital role in ensuring machining accuracy and enhancing productivity. This article will provide an in-depth overview of Milling Chucks, including their types, features, and applications.

1. Basic Concepts of Milling Chucks

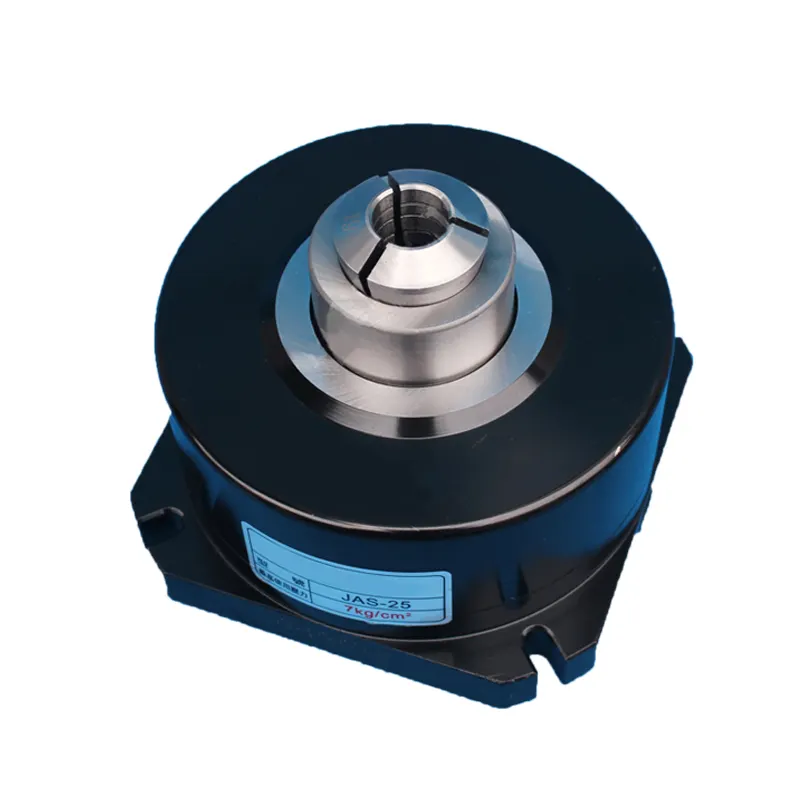

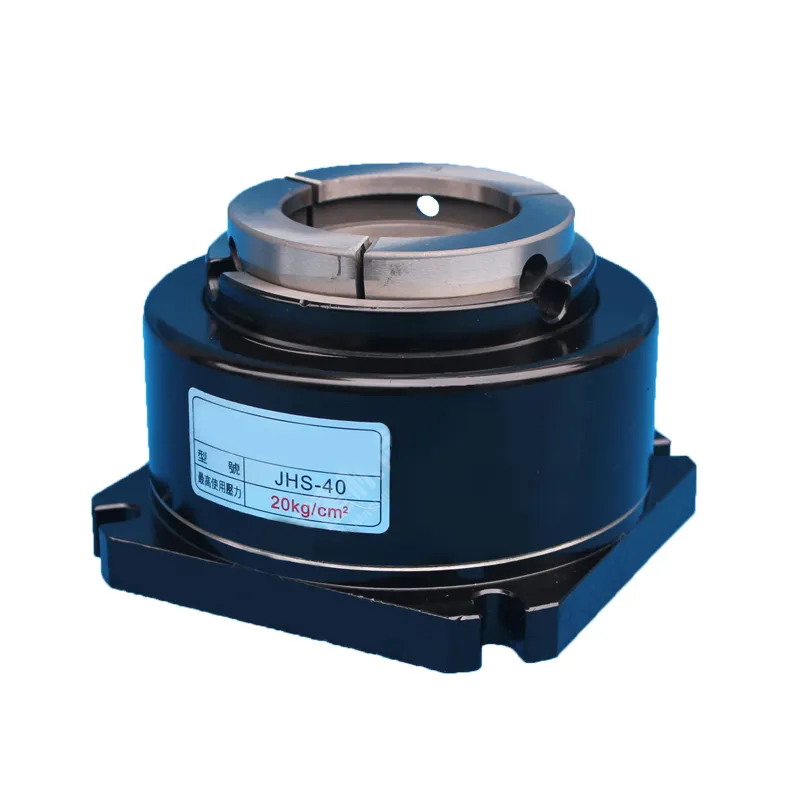

A Milling Chuck is a device used to secure milling cutters. It interfaces with the machine tool spindle to hold the cutting tool firmly in place. Depending on the specific requirements, Milling Chucks can be categorized into various types, such as standard, high-speed, high-precision, and automatic tool change chucks, each designed to meet particular machining needs.

2. Main Types of Milling Chucks

Standard Milling Chuck: Suitable for most conventional milling operations, this type is simple in design, easy to operate, and cost-effective, making it ideal for small and medium-sized enterprises.

High-Speed Milling Chuck: Designed for high-speed cutting, these chucks are made from lightweight materials to minimize rotational imbalance, thereby improving cutting speed and surface quality.

High-Precision Milling Chuck: Tailored for precision part machining, these chucks offer extremely high concentricity and repeatable positioning accuracy, meeting the demands of complex part manufacturing.

Automatic Tool Change Milling Chuck: Commonly used in automated production lines and multi-task machining centers, these chucks enable rapid tool changes, significantly increasing production efficiency.

3. Features and Advantages

High Precision: Modern Milling Chucks typically achieve micron-level positioning accuracy, ensuring consistent and high-quality parts.

Stability: High-quality Milling Chucks maintain stable performance under prolonged and intense working conditions, reducing the risk of workpiece damage due to unstable clamping.

Versatility: Many Milling Chucks support multiple tool sizes, enhancing the flexibility and adaptability of the equipment.

Ease of Maintenance: Most Milling Chucks are designed for easy cleaning and maintenance, reducing ongoing operational costs.

4. Application Examples

Milling Chucks are widely used in industries such as automotive manufacturing, aerospace, and precision instruments. For instance, in automotive part production, high-precision Milling Chucks can achieve fine machining of critical components like engine blocks and crankshafts. In the aerospace sector, automatic tool change Milling Chucks can handle the continuous machining of complex parts, significantly boosting production efficiency.

5. Future Trends

As the manufacturing industry moves towards smarter and greener practices, future Milling Chucks will focus more on environmental performance, intelligent control, and seamless integration with automation systems. Additionally, advancements in material technology will drive the development of lighter and stronger Milling Chucks.

Conclusion

The Milling Chuck is a fundamental tool in the machining industry, crucial for achieving efficient and precise results. Through continuous technological innovation and optimization, Milling Chucks will continue to provide advanced machining solutions across various sectors. Whether in automotive, aerospace, or other precision manufacturing fields, the Milling Chuck remains an indispensable component for high-quality production.