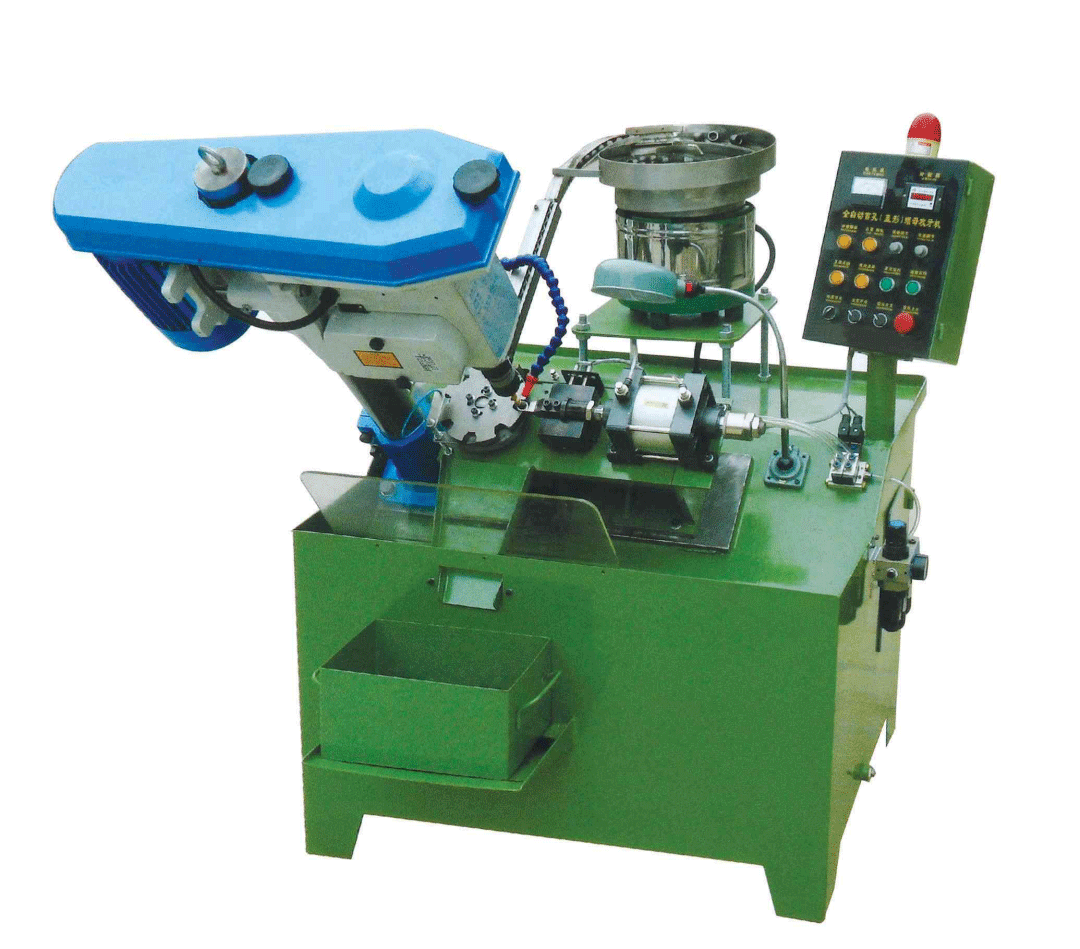

Nut Tapping Machine: A Precision Tool in Industrial Manufacturing

Introduction

In the realm of industrial manufacturing, the nut tapping machine is an indispensable precision tool used for threading holes in metal parts to install nuts or other fasteners. This machine is widely appreciated for its high efficiency, precision, and ease of operation.

Working Principle

Nut tapping machines operate by rotating one or more cutting tools, known as taps, which gradually cut into the material to form threads. This process can be manual or automated, depending on the design and capabilities of the machine.

Features

High Efficiency

- Rapid Processing: Automated nut tapping machines can complete the threading of multiple holes in a very short time.

- Mass Production: Suitable for large-scale production, reducing manual operations and enhancing production efficiency.

High Precision

- Exact Control: Advanced control systems ensure the accuracy of the threads, minimizing errors.

- Consistency: Each machined thread hole is highly consistent, ensuring product quality.

Easy Operation

- User Interface: An intuitive user interface allows operators to quickly become proficient.

- Automation: Many modern nut tapping machines support automated operations, reducing manual intervention.

Application Fields

Nut tapping machines are widely used in industries such as automotive manufacturing, aerospace, mechanical processing, and electronic equipment, where they are crucial for ensuring the structural strength and reliability of products.

Technical Specifications

- Processing Range: Depending on the machine model, different diameters and lengths of thread holes can be machined.

- Tap Material: Taps made from high-strength alloy materials ensure durability and cutting performance.

- Control System: Advanced numerical control systems support various programming options to accommodate different processing needs.

Maintenance and Care

- Regular Inspection: Regularly check for wear on taps and replace them in a timely manner.

- Lubrication: Ensure that all parts of the machine are properly lubricated to extend their service life.

- Cleaning: Clean the machine after work to remove metal shavings and dust.

Conclusion

The nut tapping machine is an integral part of modern industrial manufacturing, not only improving production efficiency but also ensuring product quality and consistency. With continuous technological advancements, future nut tapping machines will be more intelligent and automated, bringing more convenience to the manufacturing industry.