In high-stakes manufacturing environments, the reliability of CNC lathe machine parts directly impacts productivity, precision, and long-term operational costs. The Heavy Drilling and Tapping Center Series Lathe Machine V-600 exemplifies engineering excellence, offering TOC clients a robust solution for industries ranging from automotive to aerospace. Designed with industrial-grade components, this machine ensures consistent performance in demanding applications like shaft production, prototyping, and complex threading operations.

Critical CNC Lathe Machine Parts and Their Advantages

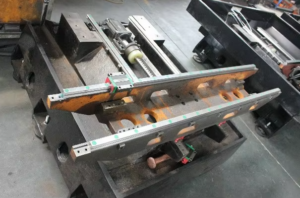

- High-Rigidity Bed: Constructed to absorb vibrations and resist deformation, ensuring stability during high-speed drilling, tapping, and turning.

- Dual-Function Headstock: Integrates a powerful motor and precision spindle for rotational accuracy up to 0.001mm tolerance, ideal for aerospace components.

- Modular Tailstock: Supports heavy workpieces and accommodates drilling tools, enabling seamless transitions between operations without recalibration.

- Automated Carriage System: Equipped with programmable feed mechanisms, reducing cycle times by 30% compared to manual systems.

- Multi-Tool Cross Slide: Enables lateral cutting tool adjustments for complex facing and grooving tasks, minimizing setup downtime.

Applications Driving Efficiency

From mass-producing automotive bushings to crafting custom medical device prototypes, the V-600’s CNC lathe machine parts deliver versatility and precision. Key benefits include:

- Reduced Material Waste: Adaptive speed control optimizes cuts for metals, plastics, and composites, minimizing scrap rates.

- 24/7 Operational Readiness: Durable components withstand continuous use in harsh industrial environments, backed by IP65-equivalent protection.

- Labor Cost Savings: Automated tool changes and programmable workflows reduce dependency on skilled operators.

Strategic Investment for Competitive Manufacturing

The Heavy Drilling and Tapping Center Series Lathe Machine V-600 transforms CNC lathe machine parts into long-term assets. Its modular design allows future upgrades, while compatibility with CAD/CAM software ensures agility in adapting to design changes.

Upgrade Your Production Line Today

Maximize ROI with CNC lathe machine parts engineered for precision and endurance. Contact us to schedule a demo or request a customized cost-benefit analysis—equip your workshop with technology designed to outperform and outlast!