Description

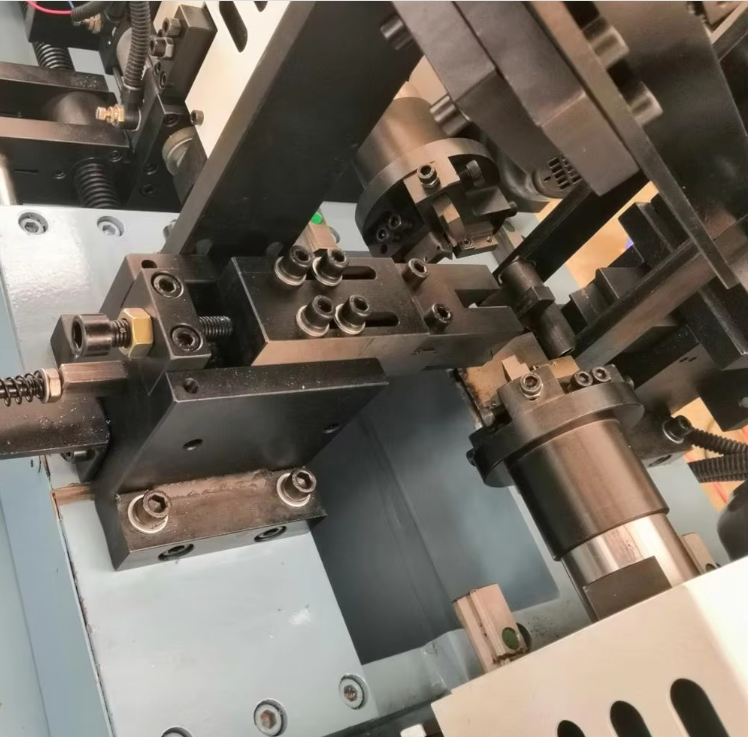

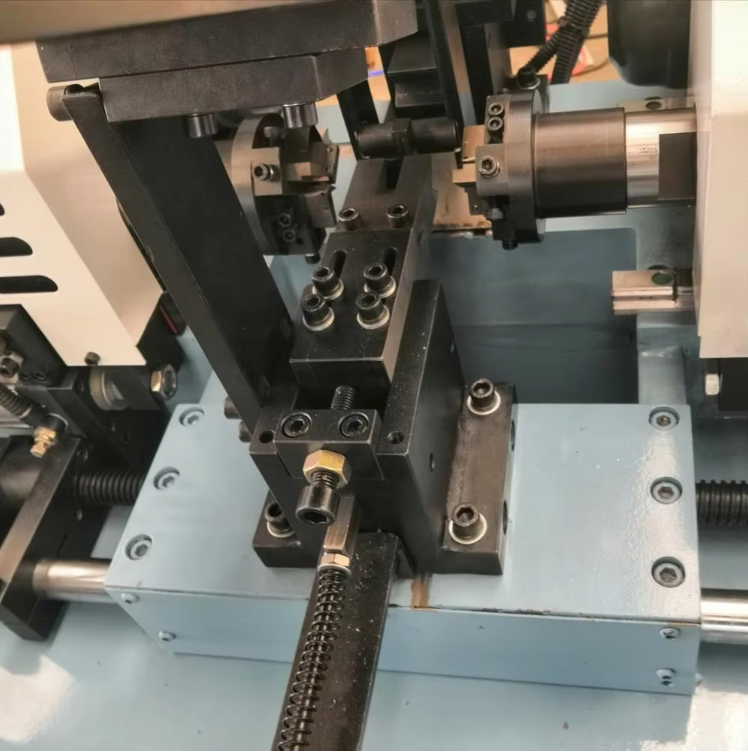

Automatic double head round rod pipe pneumatic stud bolt chamfering machine

Key Features

- Automated Operation: Many chamfering machines are automated, allowing for consistent and precise chamfering without manual intervention.

- Adjustable Angles: Capable of creating chamfers at various angles, typically ranging from 15 to 45 degrees, depending on the machine design.

- Multiple Tool Options: Equipped with various cutting tools, such as end mills or specialized chamfering tools, to accommodate different materials and thicknesses.

- Fast Setup: Designed for quick adjustments, enabling operators to switch between different chamfering tasks efficiently.

- Materials Handling: Some models include built-in material handling systems to improve productivity and reduce manual labor.

Benefits

- Increased Efficiency: Automating the chamfering process speeds up production and reduces the time spent on manual finishing.

- Consistent Quality: Ensures uniform chamfer dimensions across multiple parts, which is critical for assembly and aesthetics.

- Improved Safety: Chamfering reduces sharp edges, enhancing safety for handling and assembly.

- Versatility: Suitable for various materials, including metals, plastics, and wood, making it valuable across different industries.

Applications

- Metalworking: Commonly used in manufacturing metal parts to prepare edges for welding or assembly.

- Woodworking: Employed in furniture and cabinetry production to create aesthetically pleasing edges.

- Automotive Industry: Used for chamfering components to ensure proper fit and function in assemblies.

- Aerospace: Essential for preparing parts that require precise edge finishing for safety and performance.

Reviews

There are no reviews yet.