Description

Heavy Drilling And Tapping Center Series Lathe Machine V-600

Features

Main Components:

Bed: The foundation that supports the machine and absorbs vibrations.

Headstock: Contains the motor and spindle, which holds and rotates the workpiece.

Tailstock: Supports the other end of the workpiece and can hold tools for drilling.

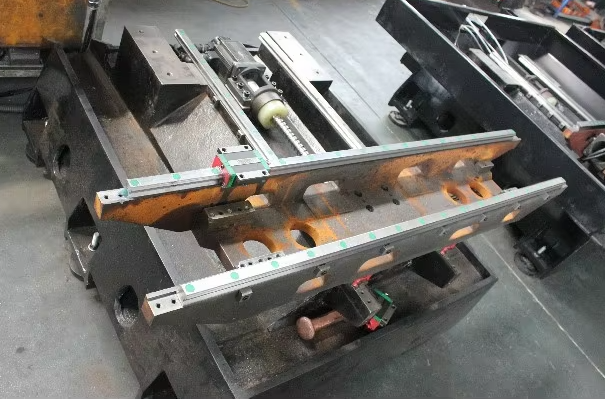

Carriage: Holds the cutting tool and moves it along the workpiece.

Cross Slide: Allows for lateral movement of the cutting tool.

Cutting Tools:

Various cutting tools can be mounted for turning, facing, drilling, and threading operations.

Speed Control:

Adjustable spindle speeds to accommodate different materials and cutting operations.

Feed Mechanism:

Allows for manual or automatic feeding of the cutting tool along the workpiece.

Types of Lathe Machines

Engine Lathe:

A versatile and common type used in workshops for various turning operations.

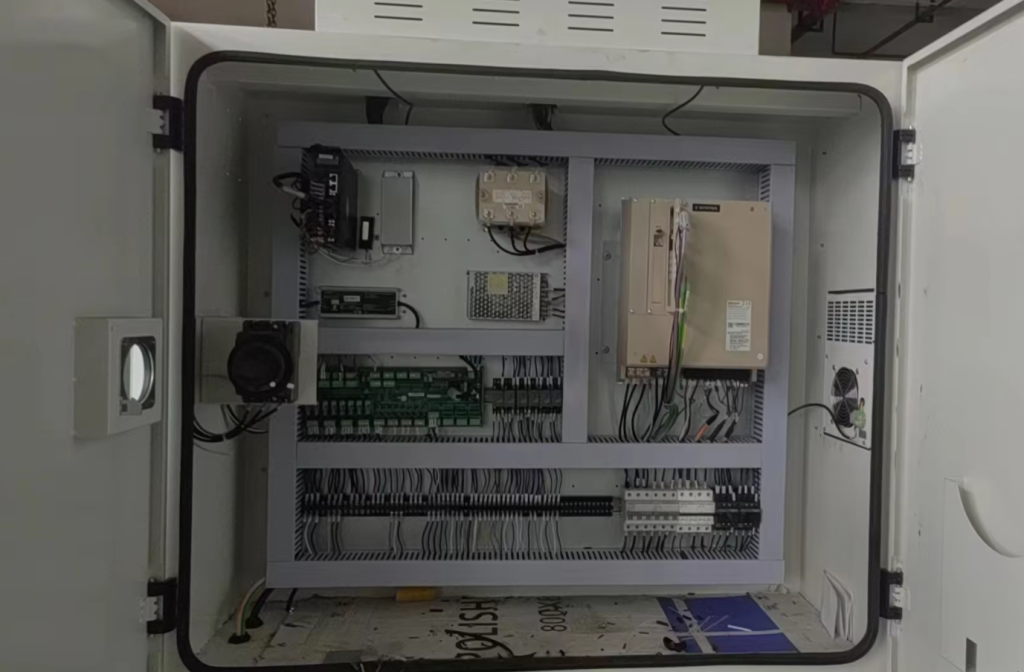

CNC Lathe:

Computer Numerical Control lathes for automated and precise manufacturing.

Turret Lathe:

Features a rotating turret that holds multiple tools, allowing for quick changes during production.

Bench Lathe:

A smaller, more portable lathe ideal for hobbyists and small workshops.

Specialty Lathes:

Includes types like wood lathes, automatic lathes, and multi-spindle lathes, designed for specific applications.

Applications

Manufacturing: Producing cylindrical parts such as shafts, pins, and bushings.

Repair: Used in maintenance for repairing worn-out parts.

Prototyping: Essential for creating prototypes and custom components.

Woodworking: Shaping wood for furniture and decorative items.

Benefits

Precision: High accuracy in producing complex shapes and dimensions.

Versatility: Capable of performing a wide range of operations with different tools.

Efficiency: Reduces material waste and enhances productivity through automation (in CNC lathes).

Durability: Built to withstand rigorous use in industrial environments.

Reviews

There are no reviews yet.