Description

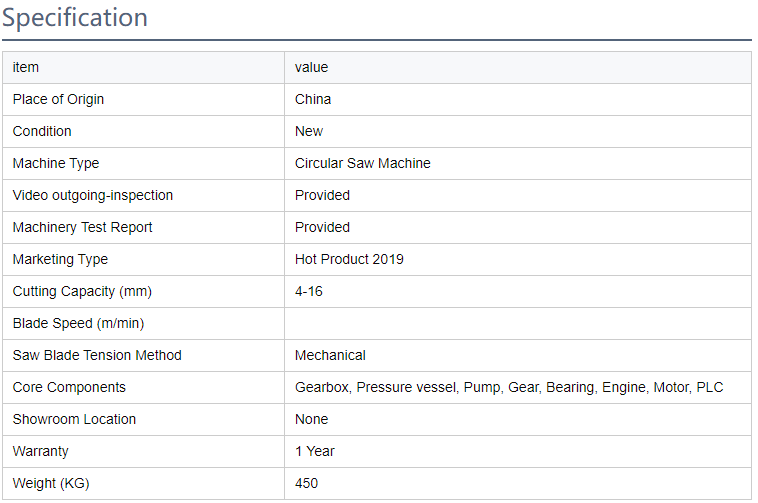

CNC full automatic Steel Bar Metal Cutting Circular Saw Machine

Key Features

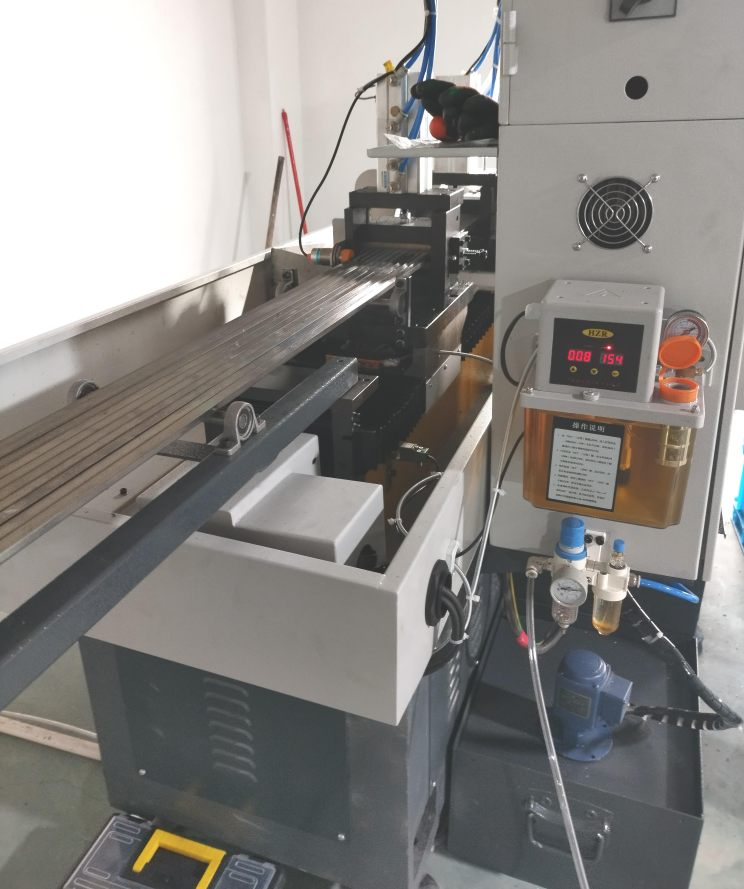

- Automatic Operation: Many bar sawing machines are automated, allowing for continuous operation and reduced manual labor.

- Precision Cutting: Equipped with advanced cutting mechanisms to ensure accurate cuts with minimal tolerances.

- Adjustable Cutting Angles: Some models allow for cutting at various angles, providing versatility for different projects.

- Different Saw Types: Can utilize various types of saw blades, including band saws, circular saws, and hacksaws, depending on the material and desired cut.

- Material Handling Systems: Often include feeding systems that automatically position and feed bars into the cutting area.

Benefits

- Increased Efficiency: Automating the cutting process speeds up production and reduces downtime associated with manual cutting.

- Consistent Quality: Ensures uniformity in cut lengths and shapes, which is essential for assembly and further processing.

- Reduced Waste: Optimized cutting paths and precise measurements lead to less material waste.

- Enhanced Safety: Minimizes operator exposure to cutting hazards by automating the feeding and cutting processes.

Applications

- Metal Fabrication: Widely used in workshops for cutting steel, aluminum, and other metals into specific lengths for further processing.

- Manufacturing: Essential for industries that require metal components in bulk, such as automotive and aerospace manufacturing.

- Construction: Used for cutting rebar and other structural components to required lengths on construction sites.

- Machine Shops: Often found in machine shops for preparing raw materials for machining processes.

Reviews

There are no reviews yet.