Description

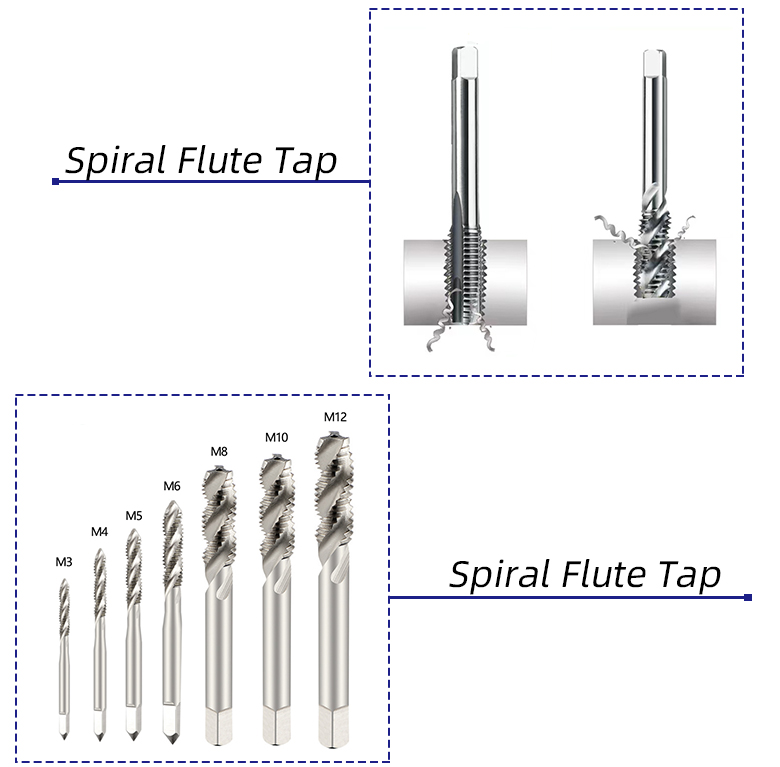

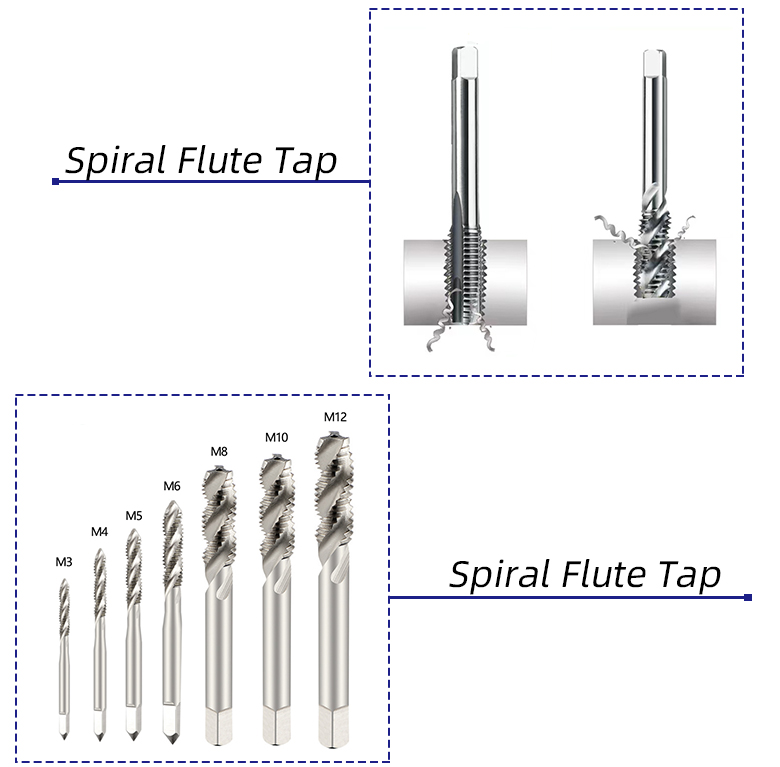

Spiral Flute Tap bit By Chinese Factory With High Quality

One-Stop Shop for Cutting-Edge Manufacturing Solutions

The spiral tap bit is a tool for processing threads and is a type of tap. It is named after its spiral flute. It is divided into left-hand spiral flute taps and right-hand spiral flute taps. When tapping with a left-hand spiral flute tap, the chips are discharged downward, which is suitable for through-hole processing; while when a right-hand spiral flute tap is tapped, the chips are discharged upward, which is more suitable for For blind hole processing.

The geometric parameters of spiral flute taps mainly include helix angle, chip flute, rake angle and relief angle. Among them, the helix angle is determined by the processing material and hardness. Generally speaking, the larger the helix angle, the better the chip removal performance. The chip flute is designed to increase the chip removal space of the tap and reduce resistance during the cutting process. The rake angle and relief angle are important parameters that affect the cutting performance of the tap. The rake angle is generally 4°~8°, and the relief angle is generally 3°~5°.

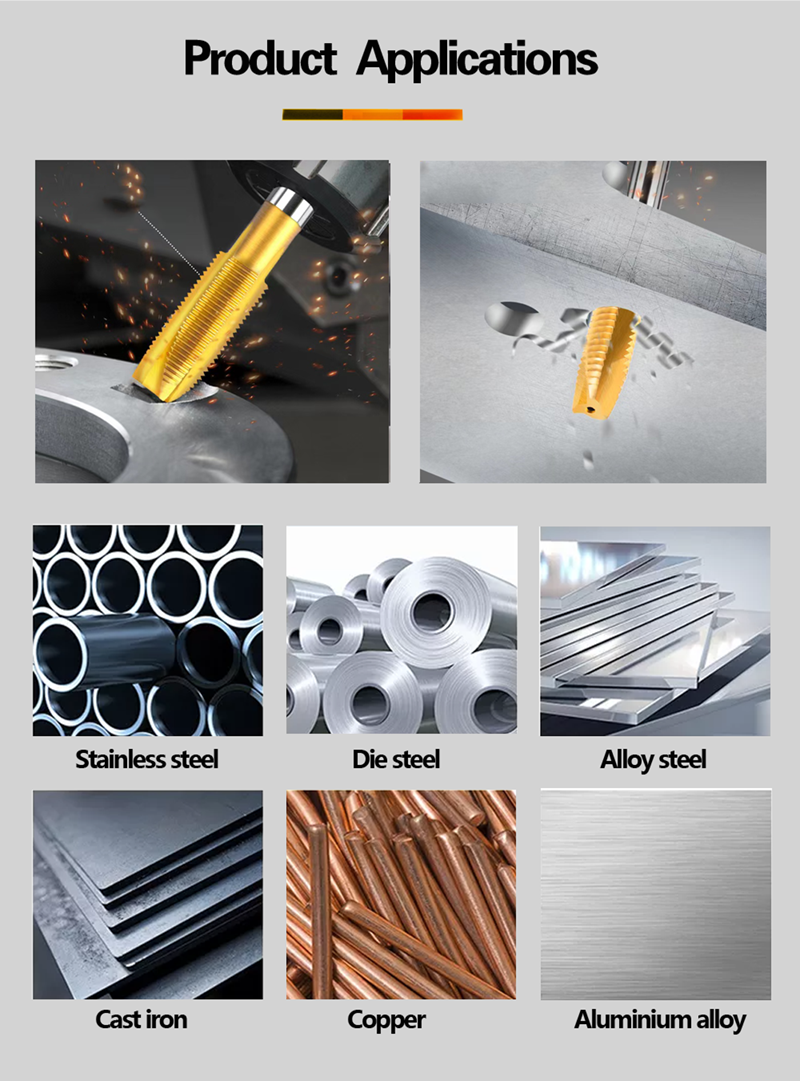

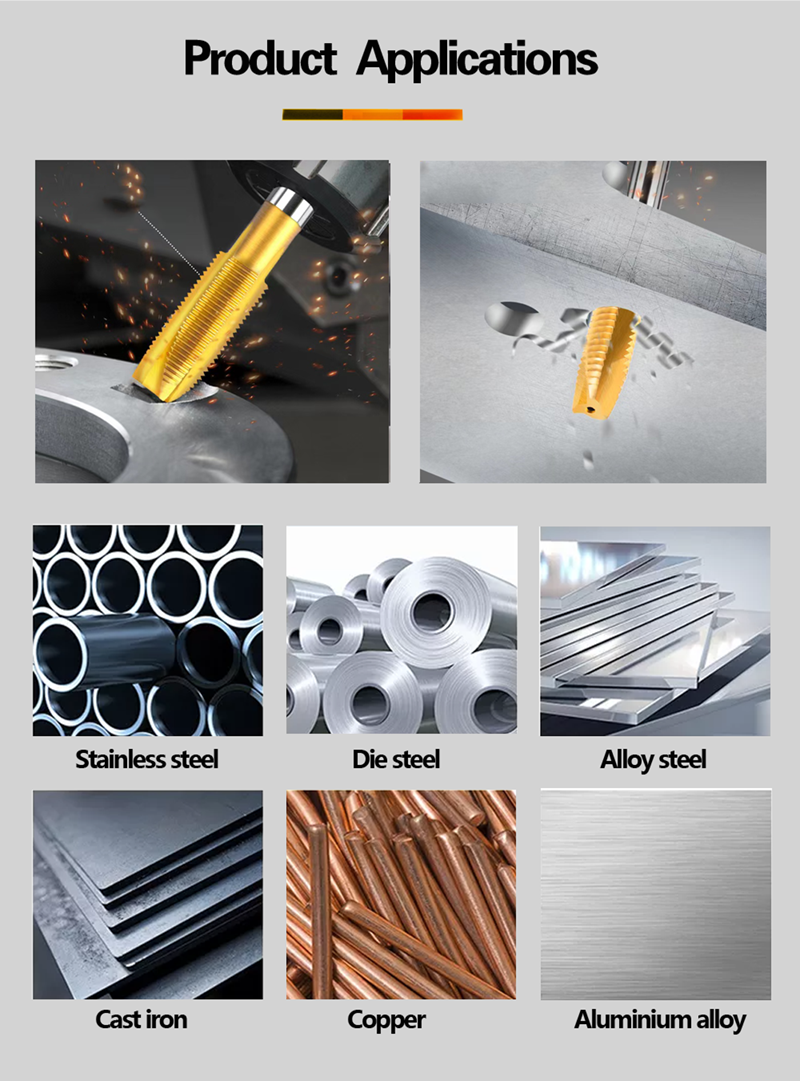

Spiral flute taps have many advantages, such as long life, high efficiency, low cost, good cooling and lubrication conditions, smooth cutting and easy insertion, and low torque. It is suitable for processing various materials, including stainless steel, alloy structural steel and various non-ferrous metals. In addition, spiral flute taps also solve the problem of processing larger threaded holes in difficult-to-machine materials, and have broad application prospects.

Spiral Flute Tap bit By Chinese Factory With High Quality

Product Enquiry

Reviews

There are no reviews yet.