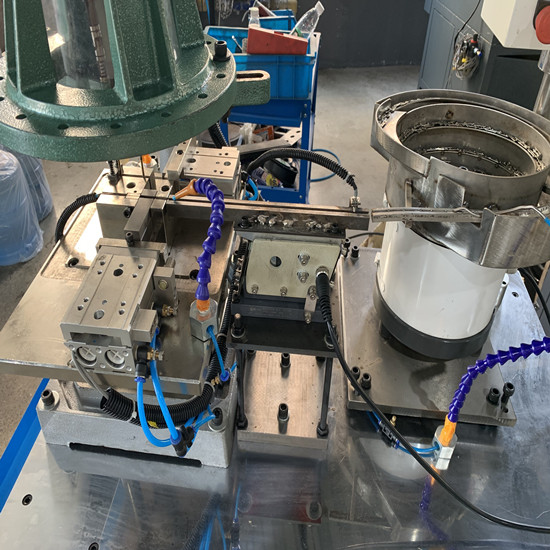

The vibrating plate is an auxiliary feeding equipment for automatic assembly or automatic processing machinery.

It can place various products in an orderly manner, cooperate with automatic assembly equipment to assemble various parts of the product into a complete product, or cooperate with automatic processing machinery to complete the processing of workpieces.

Working principle

There is a pulse electromagnet under the vibrating plate hopper, which can make the hopper vibrate in the vertical direction.

And the skewed spring plate drives the hopper to vibrate in a torsional manner around its vertical axis.

The parts in the hopper rise along the spiral track due to this vibration.

During the rising process, through a series of track selections or posture changes which make the parts can automatically enter the assembly or processing position in a consistent state according to the requirements of assembly or processing.

The purpose of its operation is to automatically and accurately transport disordered workpieces to the next process through vibration to achieve the aim by orderly placement and orientation.

Application

vibrating plate are widely used in electronics, hardware, plastics, wall clock industry, batteries, food, connectors, medical equipment, medicine, food, toys, stationery, production of daily necessities, etc.

It is necessary to handle the supply of industrial automation equipment equipment.

In addition to meeting the directional sorting of products, the vibration plate can also be used for sorting, testing, counting and packaging, etc.

Classification

1. Consists: hopper, chassis, controller, linear feeder, storage bin, and photoelectric induction system.

2.Hopper types: cylindrical hopper, spiral, linear hopper, conical hopper, aluminum alloy plate.

3.Chassis types: front pull chassis, side pull chassis, piezoelectric chassis, precision chassis, Kobelco chassis, square chassis.

4.Controllerstypes: general controller, polarization controller, frequency modulation controller, slow start controller, and digital display frequency modulation controller.

5.Piezoelectric-general-linear feeder types: 100, 120, 130, 140, 180, 200.

6.The vibration source is transported by linear motion.

7.Vibration path: The vibration path is generally divided into electromagnetic vibration path and motor vibration path. It mainly performs vertical vibration or horizontal vibration.

The motor vibration path can also achieve asynchronous three-dimensional vibration.

It is mainly used to vibrate granular and powdery materials or to vibrate slender workpieces that can freely fall in different directions into the installation position for the next round of processing.

Advantages:

Its structure and operating principle are different from traditional electromagnetic or mechanically driven vibration feeding equipment, so it has many characteristics that traditional vibration feeding equipment does not have:

(1) Simple structure, more convenient to install and maintain;

(2) Using piezoelectric sheets as the driving source does not require driving equipment such as motors and electromagnetic exciters, nor does it require mechanical transmission components such as shafts, rods, and belts. The structure is simple and easy to process and manufacture;

(3) By changing any of the amplitude, pulse width and frequency of the driving signal. The delivery rate can be scheduled with many control parameters and good controllability;

(4) No rolling inertia, almost no acceleration and deceleration process, quick start and stop, and fast response function;

(5) No interfering electromagnetic fields are generated, and it is not affected by electromagnetic interference signals;

(6) Working in the low frequency section or ultrasonic section, the noise is small;

(7) It operates under resonance or no resonance, so it consumes less energy;

(8) The driving force is slightly lacking and cannot transport heavy materials.

Therefore, this type of equipment is mostly used for micro or precise transportation of materials.