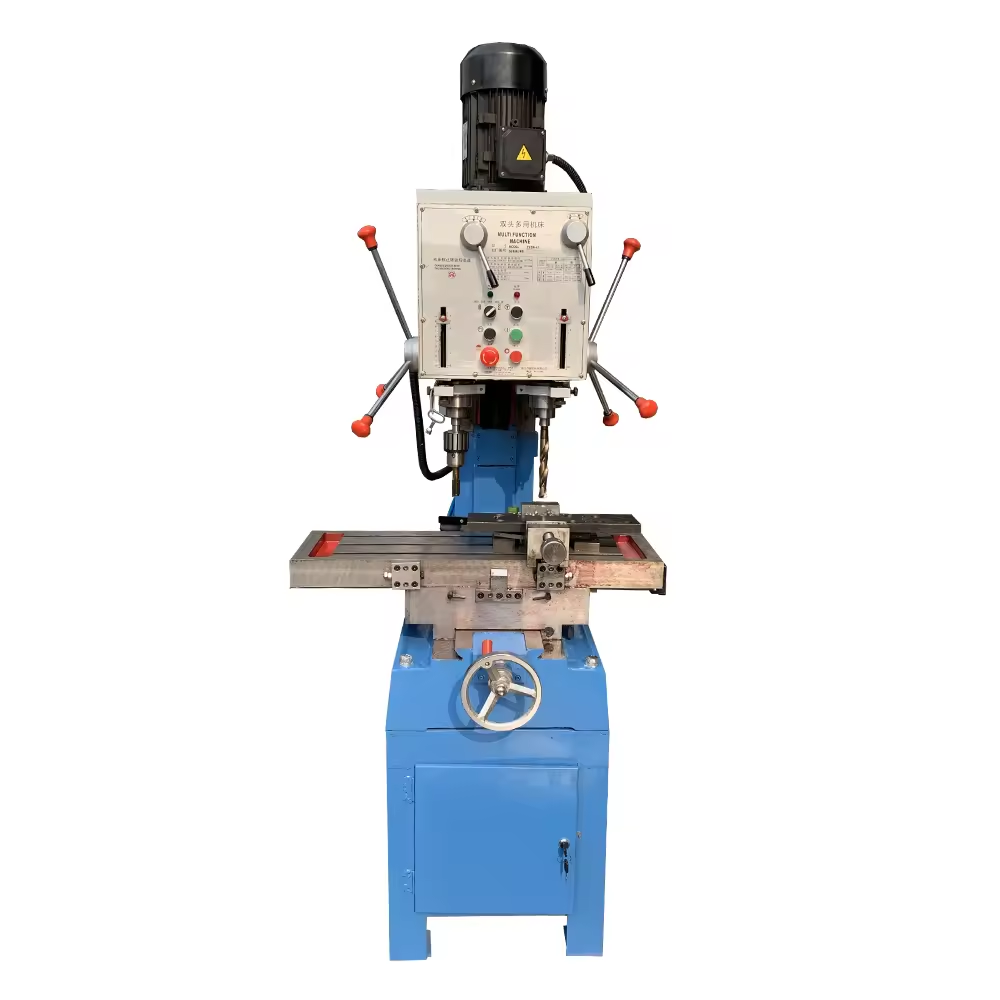

Why bench drilling machine only be used for drilling and not tapping?

Bench drilling machine are usually used for drilling operations, but in some cases, they can also be used for tapping. However, if you think that bench drills can only be used for drilling and not tapping, it may be based on the following reasons:

1.Tool selection:

Bench drills usually use straight or helical teeth tools, which are designed and used mainly for drilling. For tapping, you may need a special tapping tool, such as a tap, whose cutting edge angle and shape are more suitable for forming threads on the material.

If the cutting edge angle of the tool is too large or too blunt, or the cutting edge angle is too small or too large, it will affect the tapping effect.

2.Material hardness:

If the hardness of the material is too high, the difficulty of tapping will be greatly increased. In the tapping process, a small hole needs to be opened on the surface of the material first, and then the tool is gradually enlarged to form a thread. High-hardness materials make this process difficult.

3.Operation skills:

Tapping requires certain operating skills and experience, including choosing the right speed, feed rate and tool angle. If you use a bench drill for tapping, but the operation is improper, it may cause tapping failure or damage the tool.

4.Equipment limitations:

The structure and function of a bench drill are mainly to meet the needs of drilling, and the design and performance of tapping may be insufficient. For example, the feed mode and spindle speed adjustment range of the bench drill may not be suitable for tapping operations.

However, this does not mean that the bench drill cannot be used for tapping. In fact, by selecting suitable tools, adjusting equipment parameters and mastering correct operating skills, the bench drill can also be used for tapping. In some small workpieces or occasions where precision requirements are not high, using a bench drill for tapping is an economical and convenient method.

In summary, the view that bench drilling machine can only be used for drilling and not for tapping may be based on considerations such as tool selection, material hardness, operating skills and equipment limitations.